Welding Tool Ergonomics: Reducing Fatigue And Strain

Today we discuss Welding Tool Ergonomics. Now, you might be wondering what on earth “ergonomics” means. Well, it’s all about designing and arranging things in a way that makes them comfortable and efficient to use. And when it comes to welding tools, ergonomics plays a vital role in ensuring the comfort and safety of welders.

Imagine spending hours welding with tools that are uncomfortable to hold or use. Your hands would ache, your arms would tire, and the quality of your work could suffer. But fear not! In this article, we’ll explore practical tips and techniques to alleviate fatigue and strain while welding.

No products found.

So whether you’re a seasoned welder looking to improve your workflow or a beginner eager to learn the best practices from the start, stay with us to discover how welding tool ergonomics can make your welding journey smoother and more enjoyable. Let’s get started!

Welding Tool Ergonomics: Reducing Fatigue and Strain

Welding is a physically demanding profession that requires professionals to work long hours in challenging conditions.

One of the key concerns for welders is the risk of fatigue and strain due to improper ergonomics. In this article, we will explore the importance of welding tool ergonomics and the various ways to reduce fatigue and strain for welders.

By addressing these issues, welders can improve their overall well-being, work more efficiently, and reduce the risk of occupational injuries.

1. Understanding Ergonomics in Welding Tools:

Ergonomics refers to the science of designing tools and work environments to fit the needs and capabilities of the human body. In the context of welding, it involves optimizing the design and layout of welding tools to minimize physical stress and fatigue on the welder’s body. This includes factors such as the weight and balance of welding tools, handle design, grip comfort, and adjustability.

Proper ergonomics in welding tools can significantly reduce the risk of injuries and musculoskeletal disorders. When welders use tools that are comfortable and well-designed, they can work more efficiently and with less effort, leading to increased productivity and reduced fatigue.

Benefits of Ergonomic Welding Tools:

- Reduced risk of musculoskeletal disorders

- Improved productivity and work efficiency

- Minimized fatigue and physical strain

- Better overall work quality and precision

- Enhanced welder comfort and job satisfaction

2. Key Factors for Reducing Fatigue and Strain:

Reducing fatigue and strain in welding requires a holistic approach that considers multiple factors. Here are some key considerations to address:

a) Proper Tool Selection:

Choosing the right tools for specific welding tasks is crucial for reducing fatigue and strain. Welders should opt for lightweight tools that are easy to maneuver without compromising on performance.

The tools should have ergonomic handle designs with comfortable grips that minimize hand fatigue. Adjustable features, such as handle angles and lengths, can further enhance usability and reduce strain.

b) Work Environment Optimization:

The work environment plays a significant role in welding tool ergonomics. It is essential to ensure proper lighting, ventilation, and workspace organization to facilitate efficient and strain-free work.

Welders should have adequate space to move around, and work surfaces should be at appropriate heights to minimize unnecessary bending and reaching.

c) Personal Protective Equipment (PPE):

Wearing appropriate PPE is crucial for welders’ safety and comfort. PPE, such as welding helmets, gloves, and aprons, should be properly fitted to minimize discomfort and obstruction of movement.

Ill-fitting PPE can lead to additional strain and fatigue, so it is essential to choose the right size and invest in high-quality, ergonomic options.

d) Training and Techniques:

Proper training in welding techniques can greatly reduce physical strain and fatigue. Welders should learn and practice efficient body postures, proper lifting techniques, and ways to minimize repetitive movements.

Employing these techniques not only reduces the risk of fatigue and strain but also improves the quality and precision of welds.

e) Rest and Recovery:

Regular breaks and proper rest are vital for welders to recover from physical fatigue and strain. Rotating between different welding tasks can help distribute the workload across different muscle groups and provide relief to specific areas.

3. Innovations in Ergonomic Welding Tools:

Continual advancements in technology have led to the development of innovative welding tools designed specifically for improved ergonomics.

a) Lightweight and Portable Welding Machines:

Modern welding machines are becoming increasingly lightweight and portable, reducing the strain of carrying heavy equipment to different job sites.

Portable welding machines equipped with ergonomic handles and adjustable straps can further enhance usability and minimize fatigue during transportation.

b) Ergonomic Welding Torch Handles:

Traditional welding torch handles can be uncomfortable and lead to hand fatigue. However, newer torch handles feature ergonomic designs with contoured grips and anti-slip materials, providing a more comfortable and secure hold. These handles also incorporate features such as finger grooves and trigger locks for improved control and reduced strain.

c) Adjustable Welding Tables:

Adjustable welding tables are designed to provide welders with customizable work surface heights and angles. This enables welders to find the most comfortable and ergonomically optimal positions, reducing strain on the back, neck, and shoulders.

Some welding tables also incorporate built-in clamps and fixtures to hold workpieces securely, minimizing the need for excessive reaching or bending.

Key Takeaways: Welding Tool Ergonomics – Reducing Fatigue And Strain

- Proper ergonomics in welding tools can help reduce fatigue and strain on the body.

- Using lightweight and balanced tools can minimize the physical strain on the welder.

- Adjusting handles and grips to fit the welder’s hand size can improve comfort and control.

- Providing proper support and padding can reduce pressure points and prevent injuries.

- Taking regular breaks and stretching can help alleviate muscle fatigue during long welding sessions.

faqs for Welding Tool Ergonomics:

Ergonomics plays a crucial role in welding because it focuses on designing workspaces, tools, and equipment to fit the worker. When it comes to welding, proper ergonomics can significantly reduce fatigue and strain.

Using tools that are ergonomically designed helps minimize muscle fatigue, prevents repetitive strain injuries, and enhances overall productivity. By prioritizing ergonomics, you can create a safer and more comfortable working environment that can benefit both your short-term and long-term health.

When looking for ergonomic welding tools, there are several key features to consider. Firstly, look for tools with adjustable handles and grips. This allows you to customize the tool’s fit to your hand, reducing strain and enhancing control.

Improving your welding posture is essential for reducing strain and fatigue. Firstly, ensure that your work surface is at an appropriate height. Standing or sitting too low or high can strain your back and neck. Ideally, your work surface should be at elbow height, allowing your arms to rest at a natural angle while welding.

Yes, there are exercises specifically designed to alleviate fatigue and strain associated with welding. One effective exercise is neck stretches. Simply tilt your head to the right, hold for a few seconds, then return to the center. Repeat on the left side. This helps relieve tension in your neck and upper back.

In addition to using ergonomically designed tools and maintaining proper posture, there are other measures you can take to reduce fatigue and strain while welding. Regularly taking breaks is essential to give your body the opportunity to rest and recover. Schedule short breaks every hour to stretch, hydrate, and relax your muscles.

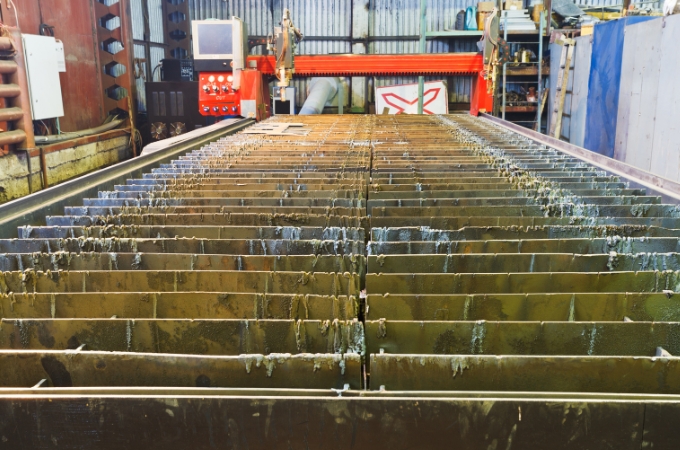

Fatigue test on welded steel specimens

Summary:

Welding tools can cause fatigue and strain, but there are ways to make them more comfortable. Ergonomic changes like adjustable handles and lightweight designs can reduce the stress on the body. Taking breaks and using proper posture can also help prevent injuries. By making these adjustments, welders can stay healthier and more productive on the job. So, next time you’re welding, remember to prioritize your well-being and use tools that reduce fatigue and strain.