best stick welding gloves

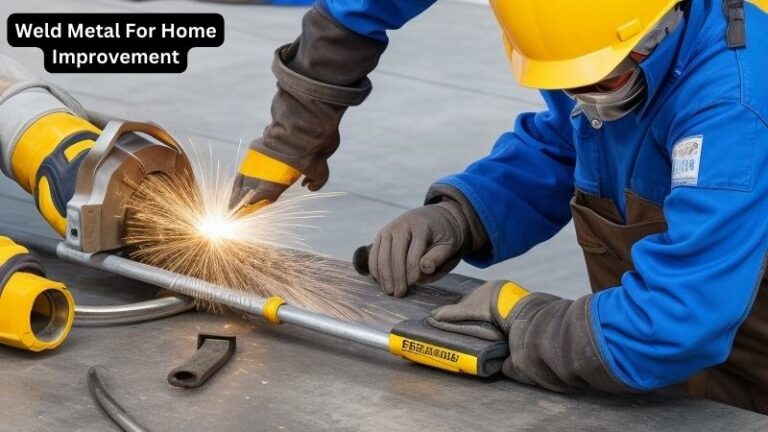

Welcome to our comprehensive guide on finding the best stick welding gloves. When it comes to stick welding, protecting your hands is of utmost importance. In this article, we will explore the top considerations for selecting the perfect pair of stick welding gloves.

From heat resistance and dexterity to durability and comfort, we’ll provide valuable insights to help you make an informed decision. Let’s dive in and find the gloves that offer optimal protection and performance.

best stick welding gloves

1. Understanding Stick Welding Gloves and Their Importance

In this section, we’ll discuss the importance of stick welding gloves and why they are crucial for welders. We’ll explore the specific hazards involved in stick welding, including heat, sparks, and molten metal, and how the right gloves can mitigate those risks.

2. Heat Resistance and Protection

One of the primary factors to consider when choosing stick welding gloves is their heat resistance. We’ll delve into the various materials used in welding gloves, such as leather, Kevlar, and aluminized fabrics, and their respective heat resistance properties. Understanding heat protection levels will help you select gloves suitable for the intensity of your welding projects.

3. Durability and Longevity

Durability is another crucial aspect to consider when evaluating stick welding gloves. In this section, we’ll explore the durability of different glove materials and stitching techniques. We’ll also provide tips on how to care for your gloves to ensure their longevity.

4. Dexterity and Grip

Stick welding requires precise hand movements and control. Therefore, it’s essential to choose gloves that offer dexterity and a secure grip. We’ll discuss the design features that enhance dexterity, such as pre-curved fingers, reinforced palms, and flexible materials. A good grip ensures better control over the welding process and reduces the risk of accidents.

5. Comfort and Fit

Comfort is a key factor in selecting stick welding gloves, as prolonged welding sessions can be physically demanding. We’ll discuss the importance of proper fit, adjustable closures, and ergonomic designs for maximum comfort.

FAQs (Frequently Asked Questions):

Yes, stick welding gloves are versatile and can be used for other welding processes, such as MIG and TIG welding. However, some specialized welding processes may require gloves with specific features, such as additional dexterity or cut resistance.

Stick welding gloves typically range from 14 to 18 inches in length. The ideal length depends on personal preference and the level of arm protection required. Longer gloves offer extended coverage, while shorter gloves provide more freedom of movement.

Stick welding gloves are primarily designed for heat and physical protection, not electrical shock protection. For electrical safety, additional precautions such as wearing insulated gloves and using proper grounding techniques are necessary.

Cleaning stick welding gloves typically involves wiping them with a damp cloth or using mild soapy water. Avoid immersing them in water or using harsh chemicals. Allow the gloves to air dry thoroughly before use.

The lifespan of stick welding gloves depends on various factors, such as frequency of use, quality of materials, and care. Generally, well-maintained gloves can last anywhere from several months to a few years. Regularly inspect your gloves for signs of wear and replace them when necessary.

final words

Selecting the best stick welding gloves is essential for your safety and welding performance. By considering factors such as heat resistance, durability, dexterity, grip, comfort, and fit, you can make an informed choice. Remember to evaluate your specific welding needs and preferences when selecting gloves. Invest in a high-quality pair of stick welding gloves, and ensure your hands are well-protected as you tackle welding projects with confidence. Happy welding!