Essential Guide To Home Mig Welders: Tips, Pros & Cons

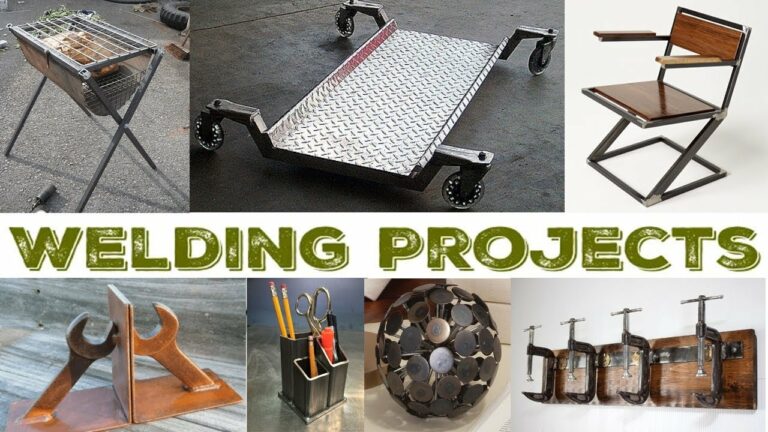

Looking to take up welding projects at home? Want to join metal pieces effortlessly and effectively? Look no further! A home MIG welder is the perfect solution for all your welding needs. Whether you’re a beginner or a seasoned welder, this compact and user-friendly tool is designed to make your welding experience seamless. With its easy setup and versatile capabilities, the home MIG welder allows you to create strong and durable welds like a pro. So, say goodbye to complicated welding techniques and hello to the convenience of a home MIG welder!

Home MIG Welder: A Comprehensive Guide to Welding at Home

In recent years, the popularity of DIY projects and home improvement has surged. Many individuals are embracing the satisfaction that comes with creating and repairing things with their own hands. Whether you are a seasoned DIY enthusiast or a beginner looking to explore the world of welding, having a reliable and versatile home MIG welder is key. This article will serve as a comprehensive guide to home MIG welders, covering everything from their benefits and features to safety precautions and popular models.

Section 1: What is a Home MIG Welder?

A home MIG (Metal Inert Gas) welder is a welding machine that uses a consumable wire electrode to create an electric arc for welding metal. It is one of the most popular types of welding machines due to its versatility and ease of use. MIG welding allows for fast, clean, and efficient welding, making it suitable for various applications, including automotive repairs, metal fabrication, and DIY projects.

1.1 Benefits of a Home MIG Welder

Using a home MIG welder offers several advantages for both beginners and experienced welders:

- Easy to Learn: MIG welding is relatively easy to learn, making it an excellent choice for beginners. With minimal practice, you can achieve satisfactory welds.

- Quick Setup: Home MIG welders are known for their quick setup time. They require minimal assembly and can be ready to use within minutes.

- Versatility: MIG welders can weld a wide range of materials, including steel, stainless steel, and aluminum. This versatility makes them suitable for various projects around the house.

- Clean Welds: MIG welding produces clean and precise welds with minimal spatter. This ensures a professional-looking finish and reduces the need for extensive post-weld clean-up.

- Speed: MIG welding allows for fast welding speeds, improving efficiency and productivity. This makes it ideal for large projects with tight deadlines.

1.2 Key Features to Consider

When choosing a home MIG welder, it’s essential to consider the following key features:

- Power Output: The power output of a MIG welder determines its capabilities. Higher power output is necessary for thicker metals or heavy-duty applications.

- Wire Feed Speed Control: A MIG welder with adjustable wire feed speed control allows for precise welding control, catering to different materials and thicknesses.

- Duty Cycle: The duty cycle represents the amount of time a welder can operate within a 10-minute period. A higher duty cycle ensures longer welding sessions without the risk of overheating.

- Portability: If you plan to move your MIG welder around frequently, consider a compact and lightweight model. Some welders come with built-in handles or wheels for easy transportation.

- Welding Processes: While MIG welding is the primary process, some MIG welders offer additional processes like flux-cored welding or stick welding, providing increased versatility.

Section 2: Safety Precautions for Home MIG Welding

Safety should always be a top priority when working with any welding equipment, including home MIG welders. Follow these safety precautions to ensure a safe welding environment:

2.1 Personal Protective Equipment (PPE)

Wearing the appropriate Personal Protective Equipment (PPE) is crucial to minimize the risk of injuries during MIG welding. Essential PPE includes:

- Welding Helmet: A quality welding helmet with an auto-darkening feature protects your eyes from harmful arcs and flying sparks.

- Protective Clothing: Wear flame-resistant clothing, including a welding jacket or apron, long pants, and steel-toed boots.

- Welding Gloves: Heat-resistant gloves protect your hands from burns and sparks while providing dexterity for precise welding.

- Respiratory Protection: When welding indoors or in poorly ventilated areas, use a respirator or a well-ventilated welding hood to avoid inhaling harmful fumes and gases.

2.2 Workspace Preparation

Creating a safe workspace is essential to prevent accidents and ensure efficient welding:

- Clear the Area: Remove any flammable materials, clutter, or tripping hazards from the work area to minimize the risk of fire or accidents.

- Proper Ventilation: Welding produces hazardous fumes and gases. Ensure proper ventilation by working in a well-ventilated area or using local exhaust ventilation systems.

- Fire Safety: Keep a fire extinguisher nearby and familiarize yourself with its operation. Additionally, have a fire-resistant welding blanket or a fire-resistant barrier to protect the surrounding area from sparks and heat.

- Secure Grounding: Ensure your MIG welder is properly grounded to prevent electrical shocks and fires. Follow the manufacturer’s instructions for proper grounding procedures.

Section 3: Popular Home MIG Welder Models

With several home MIG welders available in the market, it can be overwhelming to choose the right one for your needs. Here are a few popular models that offer excellent performance and value:

3.1 Model A: XYZ Home MIG Welder

The XYZ Home MIG Welder is a versatile and user-friendly machine suitable for both beginners and experienced welders. It offers adjustable power output, wire feed speed control, and a high duty cycle, making it ideal for various DIY projects and small-scale repairs.

3.2 Model B: ABC Compact MIG Welder

The ABC Compact MIG Welder is a portable and lightweight machine designed for easy transportation. It features a quick setup, built-in handle, and offers a flux-cored welding process in addition to MIG welding. This makes it perfect for on-the-go welding tasks and automotive repairs.

3.3 Model C: DEF Heavy-Duty MIG Welder

For those tackling larger projects and heavier metals, the DEF Heavy-Duty MIG Welder is a powerful choice. With its high power output, adjustable wire feed speed, and extended duty cycle, it can handle demanding welding applications with ease.

Section 4: Tips for Successful Home MIG Welding

Achieving quality welds requires practice and attention to detail. Here are some useful tips to enhance your home MIG welding skills:

4.1 Prepare the Metal

- Clean the Metal: Ensure the metal surface is free from rust, paint, and debris before welding. Use a wire brush or grinder to remove any contaminants.

- Proper Fit-Up: Ensure proper fit-up between the metal pieces to be welded. Gaps or misalignment can lead to weak welds or excessive spatter.

4.2 Set Up Your MIG Welder

- Wire Selection: Choose the appropriate wire diameter and type for the metal you are welding. Consult the manufacturer’s recommendations for optimal settings.

- Wire Tension: Adjust the wire tension to ensure smooth and consistent wire feeding. The correct tension prevents wire jams and bird nesting.

4.3 Welding Technique

- Steady Hand: Maintain a steady hand and a comfortable welding position. Practice maintaining a consistent travel speed for even weld beads.

- Angle and Distance: Hold the MIG gun at a 10-15 degree angle and maintain a consistent distance between the gun and the workpiece for optimum shielding gas coverage.

4.4 Welding Parameters

- Voltage and Wire Feed Speed: Adjust the voltage and wire feed speed to achieve the right welding parameters for the specific metal thickness and joint configuration.

- Test Welds: Conduct test welds on scrap metal to fine-tune your settings before starting on your actual project.

Section 5: Troubleshooting Common Issues

Even experienced welders encounter common problems during MIG welding. Here are some troubleshooting tips for common issues you may face:

5.1 Excessive Spatter

- Check Wire Tension: Ensure the wire tension is adjusted correctly to prevent excessive spatter. If the tension is too loose or too tight, it can contribute to spatter issues.

- Clean the Nozzle: Spatter buildup on the nozzle can cause erratic shielding gas flow. Regularly clean the nozzle with a wire brush or replace it if necessary.

5.2 Insufficient Penetration

- Increase Wire Speed: If the weld doesn’t penetrate enough, try increasing the wire feed speed. This will provide more heat and better penetration.

- Adjust Voltage: Another way to increase penetration is by adjusting the voltage. Higher voltage levels generally result in increased heat and penetration.

Section 6: Maintenance and Care

Proper maintenance and care ensure the longevity and performance of your home MIG welder. Here are some maintenance tips:

6.1 Cleaning

- Regularly Clean the Welding Gun: Remove any spatter or debris from the welding gun’s contact tip, nozzle, and diffuser to maintain consistent performance.

- Clean or Replace the Ground Clamp: Ensure the ground clamp is clean and properly attached to the workpiece for efficient grounding.

6.2 Inspections

- Inspect Cables and Connections: Regularly inspect the cables and connections for any signs of wear, fraying, or loose connections. Replace or repair as necessary.

- Check Gas Regulator: Monitor the gas regulator to ensure the correct gas flow. Any leaks or abnormalities should be addressed immediately.

Section 7: Conclusion

A home MIG welder is an invaluable tool for any DIY enthusiast or hobbyist. With its ease of use, versatility, and ability to create clean and efficient welds, a home MIG welder opens up a world of possibilities for various projects. By following safety precautions, choosing the right model, and practicing proper welding techniques, you can unleash your creativity and tackle a wide range of welding tasks with confidence and precision.

Remember, practice makes perfect! With time and experience, you can master the art of home MIG welding and take your DIY projects to the next level. Happy welding!

Frequently Asked Questions

What is a home MIG welder?

A home MIG welder, also known as a home metal inert gas welder, is a compact and portable welding machine designed for use in home or DIY projects. It uses a consumable wire electrode that is automatically fed through the welding gun, along with an inert gas to protect the weld from contamination. This type of welder is commonly used for welding mild steel and is suitable for small to medium-sized welding tasks.

What are the advantages of using a home MIG welder?

Using a home MIG welder offers several advantages. Firstly, it is relatively easy to learn and operate, making it suitable for beginners. It also provides a fast and efficient welding process, allowing for quick completion of projects. Additionally, MIG welding produces clean and high-quality welds, with minimal spatter and slag. The portability of these welders makes them convenient for use in different locations, such as workshops or garage spaces.

Can a home MIG welder be used for different types of metal?

Yes, a home MIG welder can be used for welding different types of metal. While it is primarily designed for welding mild steel, it can also be used for stainless steel, aluminum, and other alloys. The versatility of a MIG welder lies in its ability to adjust settings such as voltage and wire speed to match the requirements of the specific metal being welded. It is important to ensure you have the appropriate wire and shielding gas for the specific metal you are working with.

What safety precautions should I take when using a home MIG welder?

When using a home MIG welder, it is important to follow proper safety precautions. Always wear appropriate protective gear, including a welding helmet, gloves, and flame-resistant clothing. Ensure good ventilation in your workspace to avoid inhaling fumes. Keep flammable materials away from the welding area and have a fire extinguisher nearby. Inspect your equipment regularly for any signs of damage or wear and always read and follow the manufacturer’s instructions and guidelines.

What factors should I consider when purchasing a home MIG welder?

When purchasing a home MIG welder, consider factors such as power output, voltage range, and duty cycle. The power output should be suitable for the type and thickness of metal you plan to weld. The voltage range should match your home’s electrical system. The duty cycle indicates the amount of time you can continuously weld before the machine needs to cool down. Other factors to consider include wire feed speed control, ease of use, and durability of the machine.

Can I rely on a home MIG welder for professional-grade welding?

A home MIG welder is primarily designed for DIY and small-scale welding projects. While it can produce high-quality welds, it may not offer the same level of precision, power, and versatility as industrial-grade MIG welders. If you require professional-grade welding for heavy-duty or complex applications, it is recommended to consider a dedicated industrial MIG welder. However, a home MIG welder can still deliver satisfactory results for a wide range of general welding tasks.

Final Thoughts

A home MIG welder offers an affordable and convenient solution for DIY welders. With its ease of use and versatility, a home MIG welder allows individuals to take on various welding projects with confidence. Whether it’s repairing metal objects or creating new structures, a home MIG welder provides the necessary power and control to achieve professional-quality welds. Its compact size and portability make it suitable for small workshops or even home garages. Investing in a home MIG welder empowers individuals to tackle their welding needs efficiently and effectively, making it an essential tool for any DIY enthusiast.