Home Welding Jobs: Your Ultimate Guide To Success

Looking for a way to earn extra income from the comfort of your own home? Home welding jobs might just be the answer you’ve been searching for. Whether you’re a seasoned welder or looking to delve into the world of metalwork, there are plenty of opportunities available to showcase your skills and make money without stepping foot outside your front door. In this article, we’ll explore the exciting possibilities of home welding jobs and how you can turn your hobby or passion into a profitable venture. So, grab your welding helmet and let’s dive in!

Home Welding Jobs

Introduction

If you’re passionate about welding and have the necessary skills, why not consider pursuing home welding jobs? Working from the comfort of your own space not only provides convenience but also opens up opportunities for creative projects, extra income, and personal growth. Whether you’re a seasoned welder or just starting out, this article will delve into the world of home welding jobs, exploring various aspects, techniques, and potential projects you can undertake.

1. Setting Up Your Home Welding Workshop

Creating a Dedicated Workspace

To embark on your home welding journey, the first step is to set up a dedicated workspace. Consider the following aspects:

- Identify an area in your home where you can safely carry out welding activities without posing a risk to yourself or others.

- Ensure proper ventilation in the workshop to minimize the inhalation of harmful fumes.

- Invest in safety equipment, such as welding helmets, gloves, and aprons, to protect yourself from potential hazards.

Equipping Your Workshop

Having the right equipment is crucial for successful welding projects. Here are some essential tools and machinery you’ll need:

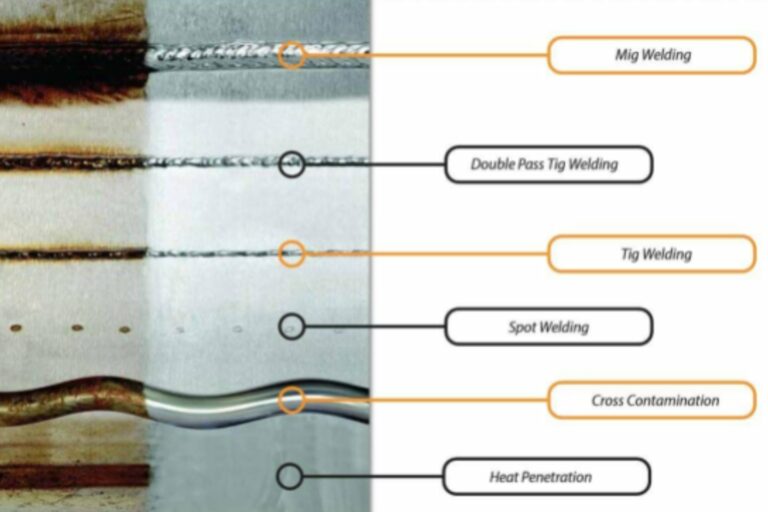

- A welding machine: Choose a machine suitable for the type of welding you’ll be doing, such as MIG, TIG, or stick welding.

- Welding accessories: Stock up on welding electrodes, filler metals, and fluxes, depending on your specific welding process.

- Workbench and clamps: Invest in a sturdy workbench and a variety of clamps to secure your workpieces in place.

- Grinding and cutting tools: Angle grinders, plasma cutters, and cutting torches are essential for preparing and shaping metal.

2. Types of Home Welding Jobs

Repair and Maintenance

One common type of home welding job involves repairing and maintaining various metal objects around the house. This can include fixing broken furniture, gates, fences, or even vehicles. By offering your welding services for small repair jobs, you can save people money and extend the lifespan of their belongings.

Custom Fabrication

If you have a flair for creativity, custom fabrication projects are a great way to showcase your welding skills. You can create unique metal artwork, personalized signs, garden sculptures, or even furniture pieces. Custom fabrication allows you to unleash your imagination and produce one-of-a-kind items that cater to individual tastes and preferences.

Automotive Welding

Automotive welding involves working on vehicles, from making repairs to modifying components. Whether it’s repairing a damaged exhaust system, fabricating custom brackets, or reinforcing chassis components, automotive welding offers a wide range of opportunities. Building relationships with local car enthusiasts or partnering with auto repair shops can help you secure consistent automotive welding projects.

Construction and Structural Welding

For those with a background in construction or a keen interest in structural engineering, home welding jobs can extend to construction projects. This may involve creating metal frameworks, reinforcing structures, or working on home improvement projects. Collaborating with contractors or working as a subcontractor in the construction industry can provide a steady stream of welding opportunities.

3. Marketing Your Home Welding Services

Building an Online Presence

In today’s digital world, establishing an online presence is essential for promoting your home welding services. Here are some ways to market yourself effectively:

- Create a professional website showcasing your portfolio, describing the services you offer, and providing contact information for potential customers.

- Use social media platforms to share images of your work, engage with the welding community, and reach out to potential clients.

- Network with local businesses, contractors, and community organizations to spread the word about your services.

Word-of-Mouth Referrals

Offering quality work and exceptional customer service is key to generating positive word-of-mouth referrals. Encourage satisfied customers to spread the word about your welding services, and consider implementing a referral program to incentivize them further. Building a reputation for reliability and craftsmanship will help you secure a steady stream of home welding jobs.

4. Safety Precautions for Home Welding

Protective Gear

Prioritizing safety should be a non-negotiable aspect of any welding project. Some essential safety measures include:

- Wearing a welding helmet with the appropriate shade level to protect your eyes from harmful ultraviolet (UV) and infrared (IR) radiation.

- Using flame-resistant clothing, gloves, and footwear to shield yourself from sparks and potential burns.

- Ensuring proper respiratory protection, such as a respirator or a welding hood with a built-in air filtration system, to prevent inhalation of hazardous fumes.

Workspace Safety

Creating a safe working environment is equally important. Consider the following precautions:

- Clear any flammable materials or liquids from your workspace to reduce the risk of fire hazards.

- Provide adequate ventilation to minimize the accumulation of welding fumes and gases, as they can be harmful when inhaled in large quantities.

- Keep a fire extinguisher nearby to promptly address any potential fires.

Training and Education

Regularly updating your knowledge and skills through welding courses, certifications, and workshops will help you stay up-to-date with the latest safety practices. Familiarize yourself with industry standards and techniques to ensure you’re adhering to best practices in your home welding jobs.

5. Financial Considerations

Pricing Your Services

Determining the right pricing structure for your home welding services is essential to ensure profitability. Consider the following factors when pricing your work:

- Time and labor involved in each project

- Cost of materials and consumables

- Market rates in your area

- Overhead costs and business expenses

Tracking Income and Expenses

Running a home welding business requires diligent financial tracking. Consider using accounting software to record income, track expenses, and generate invoices for your clients. This will help you monitor the financial health of your business and make informed decisions for growth and profitability.

In conclusion, home welding jobs open up a world of possibilities for both experienced and aspiring welders. By setting up a dedicated workshop, marketing your services effectively, prioritizing safety, and managing your finances, you can embark on a fulfilling and profitable welding journey from the comfort of your own home. Whether you choose to take on repair jobs, engage in custom fabrication, work on automotive projects, or contribute to construction endeavors, honing your welding skills at home can provide a rewarding and flexible career path. So, unleash your creativity, showcase your expertise, and embrace the exciting realm of home welding jobs.

Frequently Asked Questions

What safety equipment do I need for home welding jobs?

When engaging in welding projects at home, it is crucial to prioritize safety. Some essential safety equipment includes welding gloves, a welding helmet with a proper lens shade, welding jacket or apron, safety glasses, and ear protection. Additionally, ensure proper ventilation in your workspace and have a fire extinguisher nearby.

What types of welding machines are suitable for home welding jobs?

For home welding jobs, some commonly used types of welding machines include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welders. These machines offer versatility and ease of use for a variety of projects, depending on the materials and thicknesses you’ll be working with.

What materials can I weld at home?

With the appropriate equipment and skills, you can weld various materials at home. Common materials for home welding jobs include steel, stainless steel, aluminum, and cast iron. Ensure you have the necessary welding process, filler metal, and techniques for each specific material.

Can I learn welding on my own for home projects?

While it is possible to learn welding on your own for home projects, it is highly recommended to take a welding class or seek guidance from an experienced welder. Proper training ensures you understand the safety protocols, techniques, and equipment operation. It also improves your welding skills and reduces the risk of mistakes or accidents.

What are some common home welding projects for beginners?

For beginners, there are several simple welding projects to undertake at home. Some examples include making decorative metal art pieces, welding garden sculptures or furniture, repairing metal gates or fences, or even creating custom metal brackets or shelves. Starting with these projects can help you gain experience and confidence in your welding abilities.

Final Thoughts

In conclusion, home welding jobs offer a flexible and convenient option for those interested in pursuing a career in welding. With the necessary equipment and skills, individuals can take advantage of the growing demand for welding services and earn income from the comfort of their own homes. This opportunity allows for increased control over working hours and the potential to build a successful business in the welding industry. Home welding jobs provide a viable option for individuals looking to pursue their passion for welding while enjoying the benefits of a flexible work environment.