Industrial-Grade Welding Blankets

Today we discuss Industrial-Grade Welding Blankets. Industrial-grade welding blankets are indispensable safety tools designed to protect workers, equipment, and the environment from welding hazards in industrial settings. They are specifically engineered to withstand the intense heat, sparks, and molten metal splatter produced during welding operations. In this article, we will explore the significance of these welding blankets in industrial environments and the key features that make them stand out from regular welding blankets.

Industrial-Grade Welding Blankets:

Industrial-grade welding blankets are safety products designed to protect workers and the surrounding area from heat, spatter, slag, and sparks associated with welding operations. They are made of heavy-duty fire retardant materials such as fiberglass or ceramic cloth that can withstand temperatures up to 2000°F (1093°C).

Welding blankets should always be used when performing any kind of welding work to ensure maximum safety for the worker and those in the vicinity. Additionally, industrial-grade welding blankets also provide protection against UV light emissions from some arc welders as well as help contain fumes created by the process.

Understanding Industrial-Grade Welding Blankets:

Welding processes in industrial settings present numerous hazards, including the risk of fire, burns, and damage to nearby structures. Industrial-grade welding blankets play a crucial role in mitigating these risks. They act as a protective barrier, preventing sparks and heat from reaching flammable materials and reducing the likelihood of accidents.

No products found.

Features of Industrial-Grade Welding Blankets:

High-Temperature Resistance:

One of the primary features of industrial-grade welding blankets is their ability to withstand extreme temperatures. These blankets are engineered with advanced materials like silica and ceramic, which provide exceptional resistance to heat, ensuring optimal protection in high-temperature welding applications.

Durability and Flexibility:

Industrial-grade welding blankets are designed to be durable and flexible. The use of materials like fiberglass ensures that the blankets can endure rigorous use while maintaining their protective properties. The flexibility allows for easy handling and positioning during welding tasks.

Flame and Spark Protection:

The inherent flame resistance of industrial-grade welding blankets makes them effective in containing sparks and flames generated during welding processes. This prevents accidental fires and protects workers and equipment in the vicinity.

Choosing the Material for Industrial Welding Blankets:

Different welding applications may require specific materials to optimize performance. The three primary materials used for industrial-grade welding blankets are fiberglass, silica, and ceramic.

Fiberglass:

Fiberglass welding blankets offer excellent flexibility and durability. They are a popular choice for general welding applications due to their versatility and cost-effectiveness.

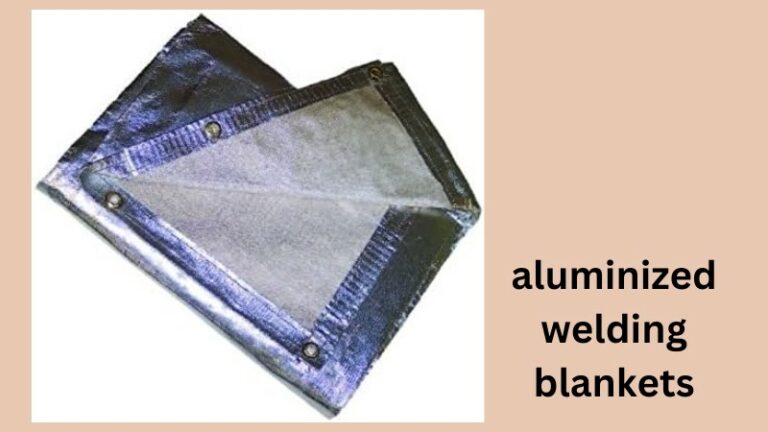

Silica:

Silica welding blankets are known for their high-temperature resistance and are often used in applications involving heavy welding work. They are ideal for scenarios where extreme heat and molten metal splatter are common.

Ceramic:

Ceramic welding blankets excel in providing protection against intense heat, making them suitable for heavy-duty welding tasks involving molten metals and other extreme conditions.

Best Practices:

Proper handling and storage of industrial-grade welding blankets are essential to ensure their longevity and effectiveness. Regular inspection and maintenance help identify any signs of wear or damage that may compromise their performance. Additionally, it is crucial to select the right welding blanket for specific welding applications to maximize safety and efficiency.

Applications

Industrial-grade welding blankets find widespread use in various industries, including:

Shipbuilding Industry

In shipyards, welding blankets are used to protect surrounding structures and equipment during shipbuilding and repair operations.

Construction and Infrastructure Projects

During construction work, welding blankets shield nearby materials and surfaces from sparks and heat generated during welding.

Automotive and Aerospace Manufacturing

In manufacturing processes like automotive and aerospace industries, welding blankets ensure worker safety and protect sensitive components.

Advantages of Industrial-Grade Welding Blankets:

Enhanced Workplace Safety

Industrial-grade welding blankets significantly enhance workplace safety by minimizing the risks associated with welding, ensuring a safer working environment for welders and others nearby.

Increased Productivity and Efficiency

With reliable protection in place, workers can focus on their welding tasks without the fear of accidents or damage, leading to increased productivity and overall efficiency.

Cost-Effectiveness

Investing in industrial-grade welding blankets ultimately saves money by reducing the potential for costly accidents, repairs, and downtime.

Limitations of Industrial-Grade Welding Blankets:

Temperature Limitations

While industrial-grade welding blankets are designed to withstand high temperatures, there are limits to their heat resistance. Extreme conditions may require additional safety measures.

Size and Weight Considerations

Some industrial-grade welding blankets can be bulky and heavy, making them challenging to handle in certain applications.

Chemical and Abrasion Resistance

While they protect against heat and sparks, not all welding blankets provide adequate resistance to certain chemicals and abrasion.

Comparing to Regular Welding Blankets:

Industrial-grade welding blankets offer specific advantages over regular welding blankets, particularly in industrial environments.

Superior Performance in Industrial Environments

Industrial-grade welding blankets are specifically engineered to handle the challenges of industrial welding, making them more suitable for heavy-duty applications.

Specificity and Adaptability

Industrial-grade welding blankets can be customized to meet the requirements of specific welding tasks, ensuring maximum protection.

Budget Considerations

While industrial-grade welding blankets may have a higher upfront cost, their enhanced performance and durability make them a cost-effective long-term investment.

Faqs for Industrial-Grade Welding Blankets:

As much as we’d love to believe it, industrial-grade welding blankets don’t possess any secret power to repel alien invasions. They’re exceptional for welding protection though!

Absolutely! While they aren’t designed for playtime, industrial-grade welding blankets can still create a cozy and unique fort experience for your kids. Just make sure to supervise their play for safety.

Certainly! Industrial-grade welding blankets typically come with a warranty or guarantee to protect against any manufacturing defects.

Absolutely! Industrial-grade welding blankets are versatile and designed to provide reliable protection for both indoor and outdoor welding applications.

These blankets are crafted from high-quality fire-resistant materials, and many are made to be environmentally friendly, ensuring safety and sustainability.

Absolutely! While it might be an unconventional choice, you can certainly get creative and fashion a welding blanket into a unique fashion-forward poncho for your beloved pet llama.

Conclusion

Industrial-grade welding blankets play a vital role in ensuring workplace safety and protection in industrial settings. With their high-temperature resistance, durability, and flexibility, they offer effective defense against welding hazards. Choosing the right material and understanding their applications can help optimize their performance in various welding scenarios.