Temperature Range For Welding Blankets

Today we discuss Temperature Range For Welding Blankets. When it comes to welding, ensuring safety is paramount. That’s where welding blankets come in handy! But have you ever wondered about the temperature range for welding blankets? Well, in this article, we’ll dive into this important topic and provide you with all the information you need. So let’s get started!

Welding blankets are designed to protect workers and materials from the extreme heat generated during welding. They create a barrier between the welding area and the surrounding environment, preventing sparks, spatter, and heat from causing any damage.

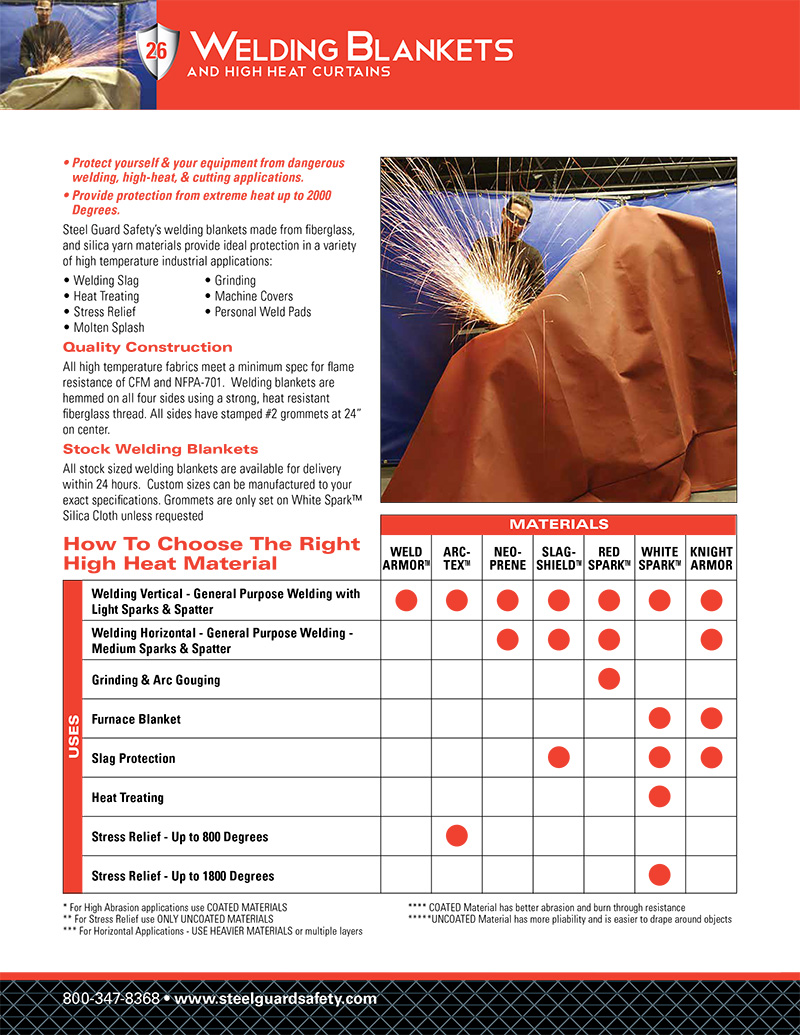

Now, let’s talk about the temperature range for welding blankets. These blankets are typically made from fire-resistant materials like fiberglass or silica fabric, which can withstand high temperatures. Most welding blankets have a temperature range of 1,000 to 1,800 degrees Fahrenheit (538 to 982 degrees Celsius).

So whether you’re a professional welder or just curious about welding safety, understanding the temperature range for welding blankets is crucial. It ensures that you choose the right blanket for your specific welding needs and stay protected in potentially hazardous environments. Let’s explore more about this topic and discover the benefits of using welding blankets.

Source: steelguardsafety.com

Exploring the Temperature Range for Welding Blankets: Protecting Against Heat

Welding blankets are essential safety tools used in various industries to protect workers and equipment from heat and sparks generated during welding processes. When selecting a welding blanket, understanding its temperature range is crucial to ensure optimal protection and prevent damage. In this article, we will delve into the temperature range for welding blankets, exploring their capabilities, benefits, and key considerations.

Basics of Welding Blankets:

Welding blankets are made from flame-resistant materials designed to withstand high temperatures and protect against sparks, molten metal, and radiant heat. These blankets act as a barrier, confining the heat and preventing it from spreading to adjacent areas or materials. They are commonly used in welding operations, cutting processes, and other applications where intense heat is generated.

The temperature range a welding blanket can handle depends on the materials used in its construction. High-quality blankets are typically manufactured using materials such as fiberglass, silica, or ceramic fibers.

These materials have exceptional thermal resistance properties, allowing them to withstand temperatures ranging from 1,000°F to 3,000°F (537°C to 1650°C).

However, it’s important to note that the temperature range may vary depending on the specific brand and model of the welding blanket.

Understanding Temperature Ratings:

When considering a welding blanket, it’s crucial to understand the temperature ratings associated with it. The temperature rating indicates the maximum temperature the blanket can handle without compromising its integrity. Exceeding the recommended temperature range can lead to the blanket becoming ineffective at protecting against heat and sparks, posing a safety risk to both workers and equipment.

Welding blanket temperature ratings are typically specified by the manufacturer and are based on laboratory testing under controlled conditions. These ratings provide users with valuable information to select the appropriate blanket for their specific application. It is essential to follow the manufacturer’s guidelines and choose a blanket with a temperature rating suitable to the expected heat intensity in the workspace.

Benefits of Temperature Range For Welding Blankets:

Using welding blankets within their specified temperature range offers several benefits. Primarily, they provide an additional layer of protection, shielding workers and materials from the dangers of welding heat. By preventing heat transfer, they minimize the risk of burns, fires, and damage to surrounding objects or structures.

Besides, welding blankets can improve the overall efficiency of welding operations. By confining heat to the desired work area, they contribute to better temperature control and reduce energy waste. Welding blankets also help to create a safer work environment by reducing the emission of harmful fumes and reducing the risk of injury or accidents caused by heat-related factors.

Key Considerations When Selecting a Welding Blanket:

When choosing a welding blanket, several factors should be taken into consideration. Beyond the temperature range, it’s important to evaluate the size and thickness of the blanket. The size should be appropriate for the work area, ensuring complete coverage and protection. The thickness of the blanket contributes to its insulation capabilities, with thicker blankets typically offering increased heat resistance.

Another important consideration is the presence of any additional features or treatments. Some welding blankets are coated or treated with fire-resistant chemicals for added protection. These coatings can enhance the durability and performance of the blanket, offering improved resistance to sparks, abrasion, and moisture.

Proper Care and Maintenance:

To ensure the longevity and effectiveness of welding blankets, it is essential to follow proper care and maintenance procedures. Regularly inspecting the blankets for signs of wear, such as fraying or holes, is crucial.

Damaged blankets should be replaced promptly to maintain optimal safety levels. Cleaning the blankets according to the manufacturer’s instructions is also important to remove any debris or contaminants that may affect their performance.

Key Takeaways: Temperature Range For Welding Blankets

- Welding blankets have a temperature range to ensure safety during welding.

- Most welding blankets can withstand temperatures up to 1,000 degrees Fahrenheit.

- It is crucial to choose a welding blanket with a temperature rating suitable for your specific welding needs.

- Lower-temperature welding blankets are available for tasks that don’t require high heat protection.

- Always refer to the manufacturer’s guidelines to ensure proper usage and safety precautions.

faqs for Temperature Range For Welding Blankets:

Welding blankets typically have temperature ranges that can vary depending on the materials used and their intended application. In general, welding blankets can withstand temperatures ranging from 1,000 to 3,000 degrees Fahrenheit (537 to 1650 degrees Celsius). It is crucial to choose a welding blanket that can handle the highest temperature of your welding application to ensure optimal protection.

Yes, there are precautions you should take when using a welding blanket. Always ensure that the welding blanket covers the entire area that needs protection from sparks, heat, and other welding-related hazards. It is essential to secure the blanket properly to prevent any gaps or openings that could allow sparks or heat to escape.

While welding blankets are primarily designed for welding applications, they can be used for various other purposes. The ability of welding blankets to withstand high temperatures makes them suitable for tasks that involve heat protection or insulation. They can be used in applications such as soldering, plumbing, roofing, and even as a fire barrier for certain industrial processes.

However, it is important to note that the specific temperature range and materials used in a welding blanket may impact its suitability for non-welding applications. Always check the manufacturer’s recommendations and guidelines to ensure the welding blanket is suitable for the specific task or application you have in mind.

If a welding blanket is exposed to temperatures beyond its recommended temperature range, it can lead to reduced effectiveness in providing protection. High temperatures can cause the blanket to degrade, melt, or even catch fire. This can result in unsafe working conditions, damage to nearby equipment or structures, and potential injury to the welder.

Conclusion:

understanding the temperature range for welding blankets is crucial to ensure the safety and effectiveness of these protective tools. By selecting a blanket within the appropriate temperature rating, workers can mitigate risks associated with welding heat and sparks. Proper care and maintenance further enhance their performance and longevity. Incorporating welding blankets into welding operations and other high-heat processes can significantly improve workplace safety and productivity.