How to maintain and care for your welding tools

Today we will discuss maintain and care for your welding tools. Welding tools are valuable assets that require proper maintenance and care to ensure their longevity and optimal performance. By implementing regular maintenance routines and following essential care practices, you can extend the lifespan of your welding tools and prevent unnecessary breakdowns.

maintain and care for your welding tools

1. Cleaning and Inspection: The Foundation of Maintenance

Regular cleaning and inspection are fundamental to the maintenance of welding tools. After each use, wipe off any debris, dust, or spatter from the tools using a clean cloth or brush. Pay special attention to the contact tips, nozzles, and electrodes of welding guns.

Additionally, inspect the tools for any signs of damage, wear, or loose connections. Identifying and addressing these issues early can prevent further damage and ensure the tools function properly.

2. Storage: Protecting Your Welding Tools

Proper storage is essential for preserving the integrity of your welding tools. Store them in a clean, dry, and well-ventilated area, away from excessive heat, moisture, and direct sunlight. Use designated storage compartments, racks, or cases to prevent tools from getting damaged or misplaced.

Secure loose cables, hoses, or wires to avoid tangling and potential tripping hazards. By providing a suitable storage environment, you can safeguard your tools from unnecessary wear and tear.

3. Calibration and Adjustment: Ensuring Accuracy

Maintaining accuracy is crucial for achieving quality welds. Regular calibration and adjustment of your welding tools help ensure their precision. Follow the manufacturer’s guidelines for calibration procedures and use specialized tools such as voltage meters and ammeters when necessary. Proper calibration and adjustment will enable your tools to deliver consistent performance, resulting in reliable welds.

4. Lubrication: Reducing Friction and Wear

Applying lubrication to the moving parts of your welding tools can significantly reduce friction and wear. Refer to the manufacturer’s recommendations for the appropriate lubricants and intervals for lubrication.

Common areas that require lubrication include hinges, slides, and gears. By keeping these components properly lubricated, you can enhance the overall efficiency and lifespan of your welding tools.

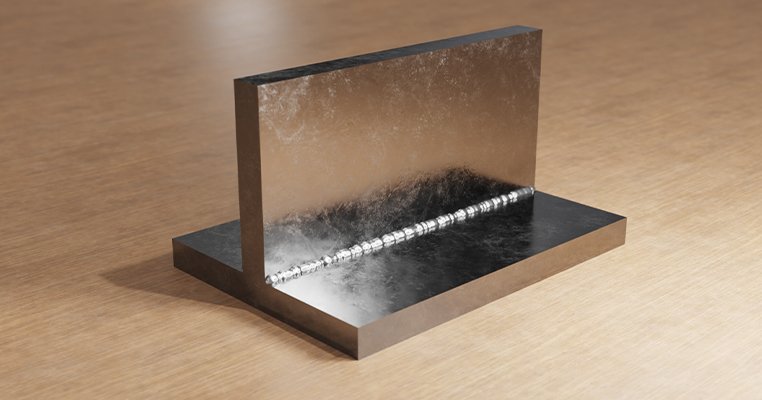

5. Replacement of Consumables: Maximizing Performance

Welding tools often have consumable components that require periodic replacement. These components include contact tips, electrodes, gas nozzles, and cutting tips, among others. Replace these consumables when they show signs of wear or when recommended by the manufacturer.

By using fresh consumables, you can ensure consistent performance, improve weld quality, and reduce the risk of tool damage.

FAQs for maintain and care for your welding tools :

It is recommended to clean your welding tools after each use to remove spatter, debris, and dust. Regular cleaning prevents build-up and keeps the tools in optimal condition.

It’s important to use lubricants specifically recommended for welding tools. Consult the manufacturer’s guidelines to determine the appropriate lubricant for each component, as using the wrong lubricant may cause damage or affect performance.

If you notice inconsistencies in weld quality, such as irregular bead appearance or improper penetration, it may be a sign that your welding tools need calibration.

When storing welding tools, ensure that they are in a secure location away from children or unauthorized personnel. Disconnect power sources and remove any flammable materials to prevent accidents. Consider locking the storage area to restrict access.

If you detect any damage during the inspection, such as frayed cables or cracked components, it’s important to address the issue promptly. Repair or replace the damaged parts to maintain the integrity and safety of your welding tools.

final words

Proper maintenance and care are vital for the longevity and optimal performance of your welding tools. By following a regular cleaning routine, storing tools appropriately, conducting calibration and adjustment when necessary, lubricating moving parts, and replacing consumables as needed, you can ensure the reliability and accuracy of your welding tools.

By prioritizing maintenance, you’ll not only extend the lifespan of your tools but also improve weld quality and reduce the risk of tool failure. Remember to consult the manufacturer’s guidelines for specific maintenance requirements and continue to invest time and effort into the care of your welding tools.