Master The Art Of Pipe Welding: A Step-By-Step Guide

If you’ve ever wondered how to weld pipe, you’ve come to the right place. Welding pipe may seem like a daunting task, but with the right knowledge and techniques, it can be easily accomplished. Whether you’re a beginner or have some welding experience, this article will guide you through the process, step by step. So grab your welding helmet and let’s dive into the world of pipe welding!

How to Weld Pipe

Welding pipes is a fundamental skill required in various industries such as construction, plumbing, and manufacturing. Whether you are a professional welder or a DIY enthusiast, understanding how to weld pipe properly is crucial for creating strong and durable connections. In this article, we will delve into the step-by-step process of welding pipes, covering everything from safety precautions to the different welding techniques you can use. So, let’s get started!

Safety Precautions for Welding Pipes

Before we proceed with the welding process, it’s essential to prioritize safety. Welding involves high temperatures and potential hazards, so taking the necessary precautions will protect you and ensure a successful welding project. Here are some safety measures to keep in mind:

1. Wear Appropriate Protective Gear

When welding pipes, it’s crucial to have the right protective gear to shield yourself from sparks, heat, and harmful radiation. Here are the essential items to wear:

– Welding helmet with a proper shade lens

– Welding gloves made from heat-resistant material

– Flame-resistant clothing, such as a welding jacket or apron

– Safety glasses to protect your eyes from sparks and debris

– Leather boots or shoes for foot protection

2. Prepare a Well-Ventilated Area

Welding produces fumes and gases that can be hazardous if inhaled. Ensure you work in a well-ventilated area to minimize health risks. If working indoors, use exhaust fans or open windows and doors to improve air circulation. Alternatively, consider using welding curtains or screens to isolate the welding area.

3. Inspect and Maintain Equipment

Before starting any welding project, thoroughly inspect your equipment for any damaged or malfunctioning parts. Ensure your welding machine, cables, and electrodes are in good condition. Follow the manufacturer’s guidelines for maintenance and replace any faulty equipment to prevent accidents.

4. Fire Prevention

Welding involves the use of intense heat and sparks, creating a fire hazard. To prevent fires, take the following precautions:

– Remove any flammable materials or substances from the welding area.

– Keep a fire extinguisher nearby and know how to use it effectively.

– Have a fire watch personnel or a fire-resistant blanket ready in case of an emergency.

Preparing the Pipe for Welding

To ensure a successful weld, proper preparation of the pipe is crucial. This involves cleaning the pipe surface and ensuring accurate alignment. Follow these steps for effective pipe preparation:

1. Clean the Pipe Surface

Cleaning the pipe surface is essential to remove dirt, oil, rust, or any other contaminants that could interfere with the welding process. Here’s how to clean the pipe:

– Use a wire brush or abrasive pad to scrub the pipe surface.

– Remove any remaining debris using a degreaser or solvent.

– Dry the pipe thoroughly before welding.

2. Align the Pipes

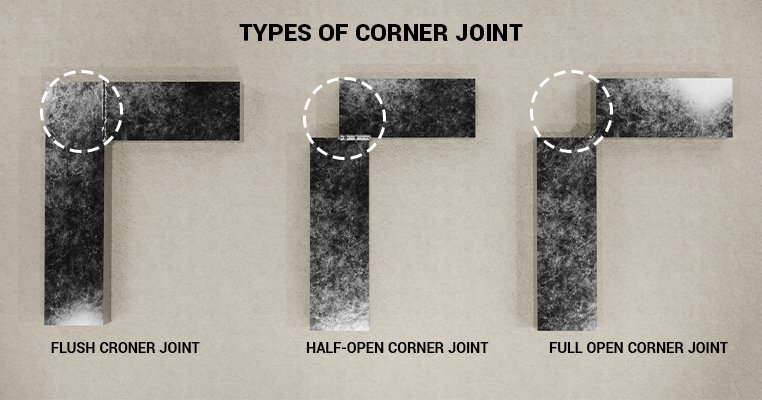

Proper alignment of the pipes ensures a strong weld and prevents leaks. Use clamps or fixtures to secure the pipes in the desired position before welding. Ensure the pipes are aligned correctly and have the proper gap for the welding process you’ll be using.

Choosing the Right Welding Technique

There are several welding techniques you can choose from when welding pipes. The selection depends on factors such as the pipe material, thickness, and the desired strength of the weld. Let’s explore some commonly used welding techniques:

1. Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding, also known as stick welding, is a popular technique for welding pipes. Here is a step-by-step guide to performing SMAW:

– Prepare the welding machine by setting the appropriate current and electrode.

– Strike an arc by touching the electrode to the pipe surface and pulling it back slightly to establish an arc.

– Maintain a consistent arc length while moving the electrode in a controlled motion along the joint.

– Fill the joint by continuously adding filler metal, known as the welding rod or electrode, into the molten pool.

– Repeat the process until you have completed the desired weld length.

2. Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding, also known as MIG welding, is another commonly used technique for welding pipes. Here’s how to perform GMAW:

– Set up the welding machine by selecting the appropriate voltage, wire feed speed, and shielding gas.

– Hold the welding gun at a slight angle and position it close to the joint.

– Activate the trigger to start the flow of shielding gas and the wire electrode.

– Move the welding gun along the joint in a controlled motion while maintaining a consistent arc length.

– Add filler wire to the joint as necessary to ensure proper weld penetration and strength.

3. Tungsten Inert Gas Welding (TIG)

Tungsten Inert Gas Welding, commonly known as TIG welding, is a precise and versatile technique often used for welding pipes made of stainless steel or aluminum. Here’s a step-by-step process for TIG welding:

– Set up the TIG welding machine by selecting the appropriate amperage, tungsten electrode, and shielding gas.

– Hold the welding torch perpendicular to the joint and establish an arc by striking the tungsten electrode against the pipe surface.

– Use both hands to control the welding torch and filler metal simultaneously.

– Move the torch along the joint in a controlled motion while maintaining a consistent arc length.

– Add filler wire to the joint as necessary to achieve the desired weld size and strength.

Testing and Inspecting the Weld

After completing the welding process, it’s important to inspect the weld to ensure its quality and adherence to standards. Here are some methods for testing and inspecting the weld:

1. Visual Inspection

Perform a visual inspection to check for any visible defects such as cracks, porosity, or incomplete fusion. Ensure the weld has proper penetration and is free from any irregularities.

2. Radiographic Testing

Radiographic testing, commonly known as X-ray testing, is used to detect internal defects or inconsistencies in the weld. This method provides a detailed view of the weld’s internal structure.

3. Ultrasonic Testing

Ultrasonic testing uses sound waves to detect flaws or variations in the weld. This method can identify defects such as cracks, inclusions, or lack of fusion.

Conclusion

Welding pipes requires skill, knowledge, and attention to detail. By following the proper safety precautions, preparing the pipes adequately, selecting the right welding technique, and conducting thorough testing and inspection, you can achieve strong and reliable pipe welds. Remember to always adhere to industry standards and guidelines for the specific application you are working on. With practice and experience, you can master the art of welding pipes and contribute to various projects in industries that rely on this essential skill.

Beginners Pipe Welding Rules to Live By

Frequently Asked Questions

What is the purpose of welding pipes?

Welding pipes is a process used to join two or more sections of pipes together permanently. It is crucial in various industries like construction, plumbing, and manufacturing, as it creates a strong and leak-proof connection between pipes, ensuring the smooth flow of fluids or gases.

What are the commonly used welding methods for pipe welding?

The most commonly used welding methods for pipe welding include Stick welding (Shielded Metal Arc Welding), MIG welding (Metal Inert Gas), TIG welding (Tungsten Inert Gas), and Flux-Cored Arc Welding. The choice of method depends on the type of pipe material, thickness, and other factors.

What safety precautions should I follow while welding pipes?

When welding pipes, it is essential to wear proper personal protective equipment (PPE), including welding gloves, a welding helmet with a face shield, flame-resistant clothing, and safety boots. Additionally, ensure proper ventilation in the area and have fire extinguishing equipment nearby.

How do I prepare the pipes before welding?

Prior to welding, it is crucial to clean the pipes to remove any dirt, rust, or contaminants that may affect the quality of the weld. Use a wire brush or sandpaper to thoroughly clean the surfaces to be welded. Additionally, align the pipes properly to ensure a precise and accurate weld.

What factors should I consider when determining the welding parameters?

Several factors influence the welding parameters for pipe welding. These include the type and thickness of the pipe material, desired weld penetration, welding method, electrode size, current settings, and joint design. It is important to consult welding codes, guidelines, or an experienced welder to determine the appropriate parameters.

Can I weld different types of pipes together?

In some cases, it is possible to weld different types of pipes together. However, it is important to consider factors such as the compatibility of materials, differences in wall thickness, and the welding method suitable for joining dissimilar pipes. It is recommended to consult welding experts or refer to industry standards for specific guidelines in such situations.

What are the potential challenges or defects to look out for when welding pipes?

When welding pipes, some common challenges or defects that may arise include lack of fusion, porosity, undercutting, excessive spatter, and joint misalignment. Regular inspection and testing, such as visual inspection, non-destructive testing, and pressure testing, will help identify and rectify any potential defects.

Final Thoughts

Welding pipes can be a challenging task, but with the right techniques and equipment, it can be accomplished successfully. By following the steps outlined in this article, you can learn how to weld pipe effectively. Understanding the proper preparation, choosing the appropriate welding method, and ensuring a secure and durable joint are all crucial aspects of pipe welding. Remember to prioritize safety at all times and take the necessary precautions to prevent accidents. With practice and experience, you can become proficient in welding pipes and achieve the desired results. So, go ahead and apply the knowledge gained from this article to master the art of welding pipes.