How to Choose the tool belt for welding

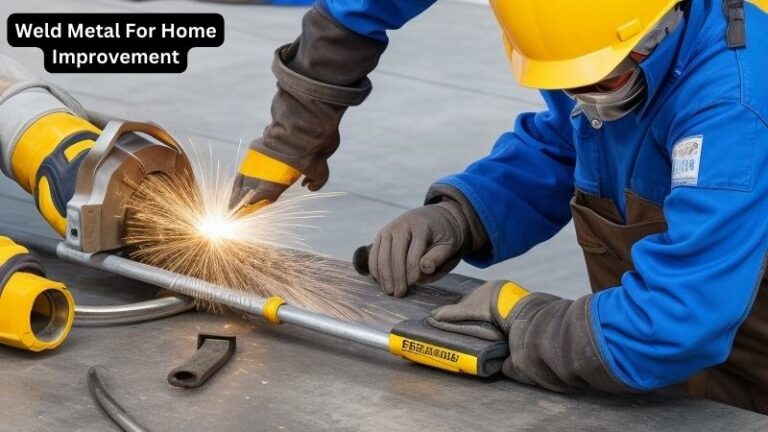

Today we discuss How to Choose the tool belt for welding. welding is a process where metal is melted and poured into a hole in the ground. This hole is then heated, and the metal is forced into the hole. The welder then uses a torch to heat the metal and create sparks. This action causes the metal to flow through the weld.

What is welding?

Welding is the process of joining metals or other materials together using heat. The melted metal is forced into a hole in the other material by using a heated flame. The first time welding was done was hundreds of years ago, and it has been used in everything from ships to cars to airplanes.

welding tool belt:

A welding tool belt is a belt that is worn by welders to hold their welding tools. It typically has several pockets and pouches to hold various tools, including pliers, wire cutters, hammers, screwdrivers, chisels, and punches. Some belts also have a built-in flashlight or a holder for a gas canister.

Welders use their tool belts to carry the tools they need to do their job. The belt allows them to keep their hands free while they work, which is helpful since they need both hands to hold the welding torch. Having all of their tools readily available on the belt makes it easy for them to quickly access what they need when they need it.

occidental welding tool belt and usage:

The Occidental welding tool belt is a belt that is worn by welders to carry the tools they need while welding.

The belt typically includes a variety of pockets and pouches for holding welding tools, such as a welder’s torch, goggles, gloves, and a safety helmet. It also may include a hammer holder and other tools to help with the welding process.

How do we weld?

Welding is a process where metal is melted and poured into a hole in the ground. This hole is then heated, and the metal is forced into the hole. The welder then uses a torch to heat the metal and create sparks. This action causes the metal to flow through the weld. The welder then uses a hammer to break through the metal and start welding.

The process includes heating up metal until it becomes liquid, which flows into a prepared hole in what’s called an ingot mold, or an existing piece of steel that has been shaped similar to what you want your finished product to look like. It’s also possible for different metal types, such as carbon steel or stainless steel, to be used in this process.

After pouring molten steel into the mold, it’s time for welding! Once you’ve reached your desired shape, you can either hammer out welds with a single blow or use multiple blows of smaller hammers on more precise pieces of metal.

After all that hard work, you’ll have created something special from raw steel–a beautiful piece of art!

What are the different types of welding tools?

There are many different types of welding tools. The most common ones are a welder’s torch (a tool used to heat metal), a hacksaw (used to cut metal), and an anvil.

There are other tools that can be used as well, such as a welding helmet, a welding-table vise, and a welding trolley. A welder must also have the proper knowledge to use these tools properly.

What is the use of a tool belt for welding?

A welding tool belt can help you keep all of your tools in one place. While this may seem like a small benefit, it does have a big impact on efficiency and safety. This is especially true for welders who use multiple tools for different jobs.

If you don’t have a tool belt, or you’re thinking about getting one, read on to find out how to pick the right tool belt for your welding needs.

What are the different types of gas welders?

There are many types of gas welders, and they each have a specific purpose.

The most common types of gas welders are wire-feed, MIG, and TIG. Wire-feed welders feed the metal in through a rotating wire. MIG and TIG welders use a gas-fueled flame to create a highly controlled electric arc for welding.

Overview of welding machines

There are three main ways to weld. The first is the most common and is called resistance welding. This method uses the heat of a torch to melt the metal while the welder uses his or her hand to form a molten stream into the molten pool on the surface. The second way is called submerged arc welding or SAW for short.

This method requires a different type of torch called a shielded metal arc welder, or SMAW for short, in order to create sparks. This method has more steps involved because it involves using an electrode and gas shield that are separate from the torch. The final way is called wire feed welding, or WFS for short. This method is special because it uses a wire rather than a torch-like other methods do.

How to choose the right tool belt for welding?

There are many different types of welding tools, and each tool has its own special requirements. It’s important to choose the right tool belt for your specific needs.

You should consider the following factors when choosing a belt:

-The size of your tools

-Whether you’re using wire feeders or breakers

-How much weight you’ll be carrying around with you

An occidental leather welding tool belt is a type of work belt that is specifically designed to protect the welder’s clothing and equipment from being damaged while in use.

The belt typically includes a number of pockets and compartments to store various welding tools and other supplies, as well as a strap system that securely attaches the belt to the welder’s waist.

The purpose of an occidental leather welding tool belt is twofold: First, it serves as an effective protection mechanism for the welder’s clothing and equipment; second, it provides convenient access to all of the necessary welding tools and supplies at all times.

Underwater welding rubber overalls and tool belts are designed to protect you from the hazards of underwater welding. They are made of durable, heavy-duty materials that will keep you safe while you are working.

Overalls come in two styles: the open-front style and the zippered style. Tool belts come in a variety of sizes and styles to fit your needs. They have pockets on the sides for carrying tools, and they often have straps that go around your waist to hold them in place.

Conclusion

The right tool belt for welding is about putting together all the components for a productive and safe welding experience. The different types of gas welders can vary in price, so it’s important to know what you’re working with and what you’re going to be using it for.

If you’re working on a DIY project, a tool belt is essential to organize all of your tools and supplies. If you need to use more than one type of gas, a tool belt is necessary to carry them safely. And if you’re working in an industrial setting, the tool belt is important for keeping all your tools in one place and organized.

If you’re interested in learning more about the best welding tool belts, check out our post on the top 10 welding tool belts!