Welding blankets for shipbuilding industry

As a part of the shipbuilding industry, you understand how integral welders are for every project. Without welding blankets – essential pieces of safety equipment that guard against sparks and splatter – your crew wouldn’t be able to carry out their work as efficiently and safely as possible.

we know just how important it is to have quality welding blankets on hand, which is why we strive to provide our customers with the highest standards of materials in all our products. Learn about why having the best welding blanket will be favorable not only for your workers but also for your business!

Welding blankets for shipbuilding industry

Welding blankets are an essential part of the shipbuilding industry, as they protect workers and equipment from potential harm caused by welding sparks or molten metal splatter. They’re designed to be flame-resistant, heat-resistant, and durable enough to withstand the rigors of a busy work environment.

The most important characteristics of welding blankets for shipbuilding are that they must be able to create a protective barrier between workers and extremely hot-burning elements such as welders and torches. In addition, they must also prevent sparks from endangering areas outdoors nearby during welding operations.

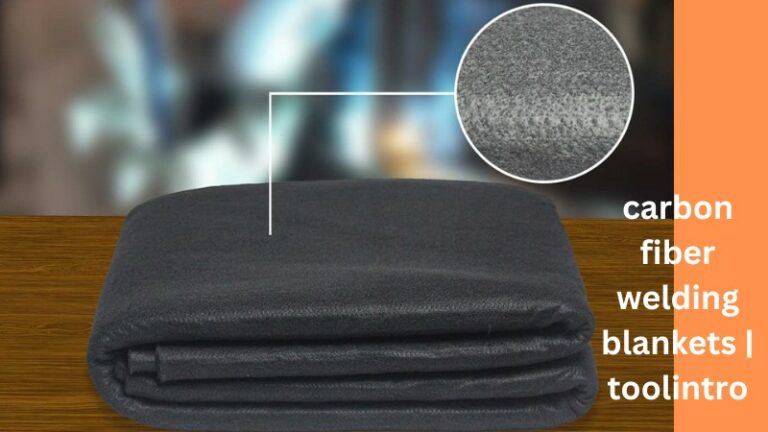

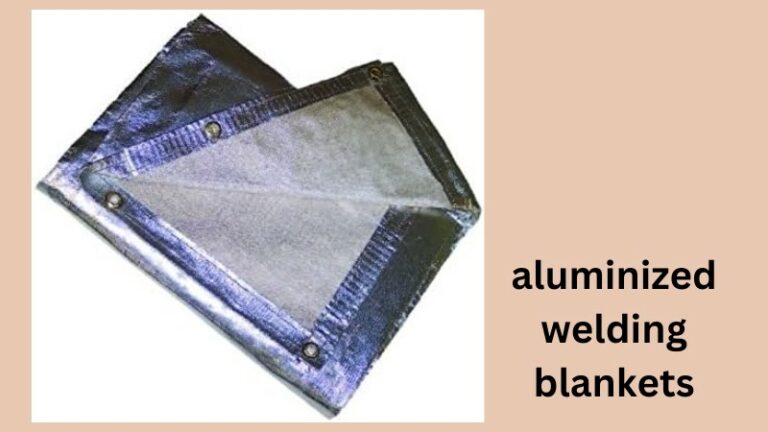

The best kind of welding blanket is made from thick layers of specialty fabrics like fiberglass with aluminium coating which helps reflect both radiant heat and electric arcs away from any viable combustibles in close vicinity.

This kind of fabric has proven itself effective time after time in firefighting environments because it can swiftly resist extreme temperatures up to 2000°F while providing adequate protection against sparks that could potentially ignite surrounding structures or personnel.

Different Types of shipbuilding industry

While welding blankets for shipbuilding are designed for safety during welding operations, they are not suitable for use as stylish beach towels for sailors during off-duty hours.

Welding blankets enhance safety during shipbuilding and welding operations by providing a protective barrier against sparks, flames, and heat. They mitigate the risk of fire hazards, burns, and damage to nearby equipment and structures.

Welding blankets for the shipbuilding industry are specialized safety tools designed to protect against the unique challenges of maritime environments. They differ from regular welding blankets by using materials that can withstand saltwater corrosion, high humidity, and extreme weather conditions at sea.

Yes, welding blankets for the shipbuilding industry are designed to be versatile and suitable for use on all types of ships, including large vessels and offshore platforms, ensuring enhanced safety during welding operations in various marine environments.

While welding blankets for shipbuilding are primarily designed for marine applications, their durability, and effectiveness make them adaptable for other industrial uses, such as in construction or manufacturing, where heat and spark protection is required.

Yes, welding blankets for shipbuilding can be customized to fit specific ship designs and requirements, ensuring optimal safety and protection during welding operations on different vessels.