6 Uses of welding blankets in construction

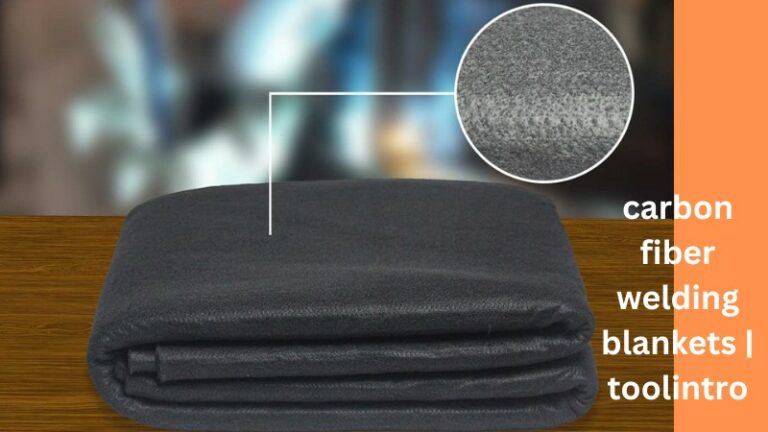

Today we discuss Uses of welding blankets in construction. Welding blankets play a crucial role in the construction industry as they offer essential protection. The use of welding blankets in construction is crafted from heat-resistant materials like fiberglass and silicone, creating a shield between the welding activity and its surroundings. the significance of using welding blankets has grown significantly due to the inherent dangers associated with welding, such as sparks, spatter, and heat radiation.

Considering that construction workers encounter these hazards daily, ensuring their safety becomes paramount. This is precisely where welding blankets step in, providing a secure and efficient solution to safeguard workers and the surrounding environment.

We will discuss the different types of welding blankets available in the market, their properties, and how they can be used to enhance safety on the job site.

1. Protects from flying debris and sparks:

One of the primary uses of welding blankets is to protect workers from flying debris and sparks that may cause severe injuries. This is crucial in welding operations where high temperatures and molten metals are present. The welding blankets act as a barrier between the welding area and the workers.

2. fires from heat exposure:

Welding blankets are designed to withstand the intense heat and sparks generated during welding. it helps to prevent fires from heat exposure and minimize the risk of damage to property.

3. Avoids damage to adjacent structures:

During welding, high temperatures and sparks can pose significant risks to surrounding materials and equipment. This helps to protect nearby surfaces, such as walls, floors, and equipment, from damage. this reduces the need for costly repairs and maintenance, saving time and money in the long run.

4. Reduces risk of equipment damage:

Hot slag and sparks produced during welding can cause damage to adjacent materials and equipment. Welding blankets create a barrier between the welding process and the surrounding area. This is particularly important in construction sites where sensitive equipment, such as electrical wiring or piping systems, could be in close proximity to the welding process.

5. safe welding environment:

welding blankets provide a safe welding environment. They are designed to contain sparks, slag, and spatter, thereby preventing them from spreading and causing fires. this can serve as a shield to protect nearby workers and equipment from the hazards of welding. Overall, the use of welding blankets provides a safe and secure environment for welding operations on construction sites.

6. Suitable for a variety of applications:

Welding blankets can be used to shield heating pipes, valves, and other equipment from welding sparks and slag. They are suitable for use in welding operations involving different types of metal, such as steel, aluminum, and copper. welding blankets can be used in different types of welding processes, including MIG, TIG, and stick welding.

Choosing the right welding blanket based on the specific application is crucial, as they vary in material, size, and temperature rating.

6 Uses of welding blankets in construction in short words:

Welding blankets find a variety of uses in the construction industry, serving as valuable tools for safety and efficiency. Here are six essential applications:

- Welding blankets act as a reliable fire barrier, preventing sparks and hot metal splatters from reaching flammable materials, structures, or vegetation nearby.

- Construction workers are shielded from heat radiation and potential burns, ensuring their safety during welding operations.

- These blankets safeguard delicate surfaces, equipment, and finished structures from welding-related damage, such as weld splatter or slag.

- In tight or confined spaces, welding blankets provide added protection as they can be maneuvered to cover specific areas effectively.

- Welding blankets serve as temporary barriers, isolating the welding area from the rest of the construction site to prevent accidents and protect nearby workers.

- Apart from welding, these blankets are useful for other hot work applications like cutting, brazing, and soldering, ensuring safety across various construction tasks.

To conclude, welding blankets are a critical component in the construction and fabrication industries. They are designed to provide superior protection from welding sparks and spatter, ensuring worker safety and preventing damage to surrounding equipment and materials.