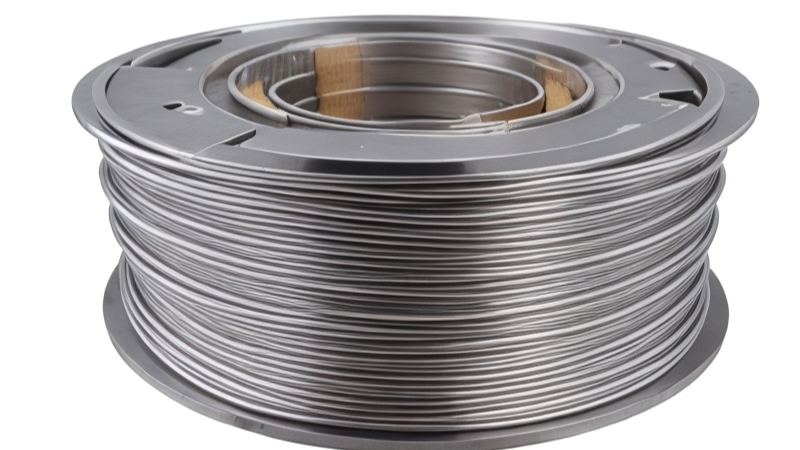

030 Flux Core Stainless Steel Welding Wire

Look no further than the 030 Flux Core Stainless Steel Welding Wire! This versatile wire is designed for easy and efficient welding, making it suitable for both professional welders and DIY enthusiasts. Whether you’re working on automotive repairs or crafting metal sculptures, this welding wire is your go-to option.

Not all welding wires are created equal, but the 030 flux core stainless steel welding wire stands out from the competition. Its flux core design eliminates the need for external shielding gas, simplifying the welding process and making it more convenient for beginners. With its 0.030-inch diameter, this wire is perfect for a wide range of stainless steel thicknesses, providing strong and durable welds every time.

Say goodbye to frustrating and inconsistent welds. The 030 flux core stainless steel welding wire offers excellent penetration and smooth arc action, ensuring high-quality welds with minimal splatter. Whether you’re joining stainless steel sheets or repairing a stainless steel pipe, this welding wire provides the reliability and performance you need for successful welding projects. Explore the world of stainless steel welding with confidence using the 030 flux core stainless steel welding wire!

All You Need to Know About 030 Flux Core Stainless Steel Welding Wire

030 flux core stainless steel welding wire is a type of welding wire specifically designed for welding stainless steel materials. It features a flux core, which means it has a powdered flux material inside the wire that creates a protective shield during the welding process. The wire is 0.030 inches in diameter, making it suitable for thin to medium stainless steel materials.

The flux core in this type of wire eliminates the need for external shielding gas, making it a popular choice for outdoor welding or situations where gas cylinders may not be practical. It provides excellent penetration and weld bead appearance, making it ideal for various applications such as automotive repairs, fabrication work, and general maintenance.

The Advantages of 030 Flux Core Stainless Steel Welding Wire

One of the main benefits of using 030 flux core stainless steel welding wire is its versatility. It can be used for both flat and vertical welding positions, offering flexibility in various welding projects. Additionally, its flux core design provides a protective shield that prevents oxidation and minimizes the risk of weld defects.

Another advantage is the wire’s ability to provide deep penetration, ensuring strong weld joints. This is particularly important when welding thicker stainless steel materials. The wire also produces clean and attractive weld beads, resulting in a professional finish.

Furthermore, 030 flux core stainless steel welding wire offers excellent deposition rates, allowing for faster welding speeds and increased productivity. It provides good tolerance to rust or contaminants on the workpiece surface, making it easier to achieve high-quality welds even in less-than-ideal conditions.

In summary, the advantages of using 030 flux core stainless steel welding wire are:

1. Versatility for various positions and applications.

2. Protective shield eliminating the need for external shielding gas.

3. Deep penetration for strong weld joints.

4. Clean and attractive weld beads.

5. Increased deposition rates for faster welding speeds.

6. Tolerance to rust and contaminants.

Tips for Using 030 Flux Core Stainless Steel Welding Wire:

To make the most out of your 030 flux core stainless steel welding wire, here are some helpful tips to keep in mind:

1. Clean the workpiece thoroughly before welding to remove any contaminants, oil, or rust that may affect the quality of the weld.

2. Adjust the welding machine settings according to the thickness of the stainless steel material being welded. Follow the manufacturer’s recommendations for voltage and wire feed speed.

3. Practice proper joint preparation and fit-up to ensure optimal penetration and weld quality. Bevel or groove the edges if required.

4. Maintain a steady travel speed during welding to achieve consistent bead appearance and proper fusion with the base metal.

5. Keep the gun angle and distance consistent throughout the welding process. It is recommended to maintain a gun angle of around 15-20 degrees and a distance of approximately 3/8 to 1/2 inch from the workpiece.

6. Use the correct polarity for your welding machine. Most flux core stainless steel wires require a reverse polarity (DCEN) setup.

7. Use proper safety gear including welding gloves, helmet, and protective clothing to protect yourself from sparks and UV radiation.

By following these tips, you can ensure optimal results when using 030 flux core stainless steel welding wire.

The Applications of 030 Flux Core Stainless Steel Welding Wire

Introduction:

Now that we have explored the features and tips for using 030 flux core stainless steel welding wire, let’s take a closer look at its applications. This versatile welding wire can be utilized in various industries and projects where stainless steel welding is required. In this section, we will discuss some of the key applications of 030 flux core stainless steel welding wire.

Automotive Repairs

When it comes to automotive repairs, stainless steel welding is often necessary. From repairing exhaust systems to fabricating custom parts, 030 flux core stainless steel welding wire is an excellent choice. Its ability to provide deep penetration and clean weld beads makes it ideal for creating strong and visually appealing welds on stainless steel components.

Fabrication Work

In the world of metal fabrication, stainless steel is a commonly used material due to its durability and corrosion resistance. 030 flux core stainless steel welding wire can be used for various fabrication projects, including constructing frames, brackets, and structures. Its versatility allows for welding in different positions, making it suitable for complex fabrication tasks.

General Maintenance

Whether you are performing repairs on household appliances or conducting maintenance on industrial equipment, 030 flux core stainless steel welding wire can be a valuable tool. Its ability to tolerate surfaces with rust or contaminants makes it ideal for weld repairs in challenging environments. Additionally, the absence of external shielding gas simplifies the welding process, making it more accessible for general maintenance purposes.

Versatile Applications

The applications of 030 flux core stainless steel welding wire are not limited to specific industries or projects. Its versatility allows it to be used in a wide range of applications, including but not limited to:

– Plumbing repairs

– Construction projects

– Sculpture and art installations

– Marine and boat repairs

– Food processing equipment

– HVAC systems

– Aerospace applications

With its versatility and excellent performance, 030 flux core stainless steel welding wire has become a go-to choice for many welding professionals and enthusiasts across different industries.

How to Choose the Right 030 Flux Core Stainless Steel Welding Wire

Introduction:

Now that you are familiar with the features, benefits, and applications of 030 flux core stainless steel welding wire, it’s essential to understand how to choose the right wire for your specific needs. Different projects and materials may require different wire specifications. In this section, we will discuss key factors to consider when selecting the right 030 flux core stainless steel welding wire.

Wire Diameter

The diameter of the welding wire plays a crucial role in the welding performance and results. 030 flux core stainless steel welding wire has a diameter of 0.030 inches, which is suitable for thin to medium stainless steel materials. If you are working with thicker materials, you may need to consider a larger diameter wire for optimal penetration.

Material Compatibility

Check the specifications of the welding wire to ensure it is compatible with the stainless steel grade you are working with. Different grades of stainless steel have varying compositions, and using the correct wire ensures proper bonding and weld strength.

Flux Type

While 030 flux core stainless steel welding wire already includes a flux core, it is important to consider the specific flux type within the wire. Different fluxes offer different properties, such as improved weld appearance, reduced spatter, or specific alloying elements. Choose a flux type that meets your project requirements and desired outcomes.

Welding Position

Consider the welding position(s) you will be working in. Some wires are better suited for flat or horizontal positions, while others perform well in vertical or overhead welding. 030 flux core stainless steel welding wire is versatile and can be used in both flat and vertical positions, making it suitable for a wide range of projects.

Brand and Quality

When it comes to welding wire, choosing a reputable brand and ensuring good quality is essential for consistent results. Look for trusted manufacturers known for their reliable welding products. Reading customer reviews and seeking recommendations can help you make an informed decision.

By considering these factors, you can choose the right 030 flux core stainless steel welding wire for your specific welding needs, ensuring optimal performance and results.

Key Takeaways: 030 Flux Core Stainless Steel Welding Wire

Here are the main points to remember about 030 flux core stainless steel welding wire:

- It is a type of welding wire specifically designed for stainless steel welding.

- It has a diameter of 0.030 inches, which is suitable for thin to medium-thickness metals.

- Flux core means that it has a hollow core filled with flux, which helps create a protective gas shield during welding.

- Stainless steel welding wire is highly resistant to corrosion and provides strong, durable welds.

- Always follow the manufacturer’s guidelines and safety precautions when using this type of welding wire.

Faqs for 030 Flux Core Stainless Steel Welding Wire:

Using 030 flux core stainless steel welding wire offers several advantages. Firstly, the flux core provides a shielding gas, eliminating the need for an additional gas cylinder. This makes it a convenient and cost-effective option.

Additionally, stainless steel is known for its corrosion resistance, making it ideal for welding projects that require durability and longevity. The 030 size allows for precise and clean welds, making it suitable for both thin and thick metals.

By using this type of welding wire, you can achieve strong welds with excellent penetration, ensuring the longevity and quality of your projects. Whether you’re working on automotive repairs or fabricating outdoor structures, 030 flux core stainless steel welding wire is a versatile and reliable choice.

While 030 flux core stainless steel welding wire is specifically designed for welding stainless steel, it can also be used on mild steel.

However, it’s important to note that the results may not be as optimal as when using the proper welding wire for each metal type. When using this welding wire on mild steel, the welds may not be as strong and may exhibit lower corrosion resistance compared to using the correct wire for mild steel.

For best results and to ensure the durability and quality of your welds, it’s recommended to use the appropriate welding wire for the specific metal you are working with. This will help you achieve stronger welds and maintain the desired properties of the metal being welded.

The flux core in 030 flux core stainless steel welding wire plays a crucial role in the quality of the weld. The flux acts as a shielding gas, protecting the weld zone from atmospheric contamination, such as oxygen and nitrogen. This shielding gas creates a stable arc and prevents the formation of defects, ensuring strong and clean welds.

Additionally, the flux core also helps in the removal of impurities during the welding process, resulting in a cleaner and more precise weld. The proper selection and use of flux core welding wire contribute significantly to the overall quality and durability of the weld, making it an essential component in achieving successful welding outcomes.

No, you cannot use 030 flux core stainless steel welding wire with an MIG welder. MIG welding requires the use of solid wire along with a separate shielding gas, typically a mixture of argon and carbon dioxide, to protect the weld pool from contaminants.

The flux core in flux core welding wire acts as a self-shielding gas, eliminating the need for an additional shielding gas source.

If you are using a MIG welder, it is essential to use the appropriate solid wire for the specific metal you are welding, along with the suitable shielding gas.

Using the correct wire and shielding gas combination will ensure proper weld quality, penetration, and overall welding performance on various metals.

030 flux core stainless steel welding wire is commonly used in various applications where stainless steel welding is required. Some common applications include automotive repairs, the fabrication of stainless steel furniture, the construction of outdoor structures like fences and railings, and the welding of stainless steel pipes and tanks.

With its excellent corrosion resistance and versatility, this welding wire is a preferred choice for professionals and DIY enthusiasts alike. Whether you’re working on a small household project or a large-scale industrial application, 030 flux core stainless steel welding wire can help you achieve durable and high-quality welds on stainless steel materials.

Source: media-amazon.com

Summary:

If you’re new to welding or just looking for an easier option, flux-core stainless steel welding wire might be the answer. It’s a type of wire that has flux inside, which helps protect the weld from contamination. This makes it more forgiving and easier to use, especially for beginners. Plus, it works on stainless steel, so you can use it for various projects like repairing appliances or creating sculptures. Just make sure to choose the right size and check the recommended settings for your welding machine. With a little practice, you’ll be creating strong and clean welds in no time!