How To Weld Metal With TIG Welding

Are you fascinated by the art of welding? Do you have a desire to master the technique of TIG welding? Look no further, as this comprehensive guide will walk you through the process of welding metal with TIG welding. Whether you’re a beginner who’s just starting out or an experienced welder looking to refine your skills, this article is your go-to resource for all things TIG welding.

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly versatile and precise welding method that can be used on a wide range of metal materials. Unlike other welding techniques, TIG welding offers exceptional control and produces clean, high-quality welds. In this article, we will delve into the fundamental principles of TIG welding, explore the equipment and materials needed, and provide step-by-step instructions to guide you through the entire welding process. Get ready to take your welding skills to new heights as we unravel the secrets of TIG welding and empower you to create durable and aesthetically pleasing metal welds.

- Prepare the metal surface by cleaning it thoroughly.

- Secure the metal pieces to be welded using clamps or fixtures.

- Choose the appropriate TIG welding machine and set the desired amperage.

- Hold the TIG torch at a 15-20 degree angle and start the arc by touching the tungsten to the metal.

- Gradually move the torch along the joint, applying filler rod to create a strong weld bead.

- Continue the process until the desired weld is achieved.

Introduction

Welding is a versatile process used in various industries to join metal parts together. TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a popular method for creating high-quality welds. This article will guide you through the step-by-step process of how to weld metal with TIG welding, ensuring you achieve strong and precise welds.

Equipment and Safety

Prior to starting the TIG welding process, it is essential to gather the necessary equipment and ensure safety precautions are in place. Here’s what you’ll need:

- TIG welding machine

- Tungsten electrode

- Welding torch

- Gas supply (typically argon)

- Welding gloves and goggles

- Protective clothing

Once you have the equipment ready, make sure you are in a well-ventilated area or have proper ventilation systems in place. It’s important to wear appropriate protective clothing, including gloves and goggles, to shield yourself from sparks and UV radiation.

Step 1: Prepare the Metal

Before you start welding, ensure that the metal surfaces you intend to join are clean and free from any contaminants, such as rust or dirt. Use a wire brush or grinder to remove any impurities, and wipe the surfaces with a solvent to ensure a clean and smooth welding area. Proper preparation of the metal is crucial for achieving strong and durable welds.

Additionally, if you are working with thicker metals, it may be necessary to bevel the edges to create a V-groove. This allows for better penetration and stronger welds. Use a grinder or specialized beveling tool to achieve the desired shape.

Step 2: Set Up the TIG Welding Machine

Next, you need to set up the TIG welding machine according to the specifications of the metal you are working with. Adjust the amperage, gas flow rate, and electrode type based on the thickness and type of metal. Refer to the machine’s manual for specific guidelines.

Insert the tungsten electrode into the welding torch and tighten it securely. The electrode should extend approximately 1/8 inch beyond the end of the torch nozzle. Ensure a proper gas flow rate to shield the weld pool effectively.

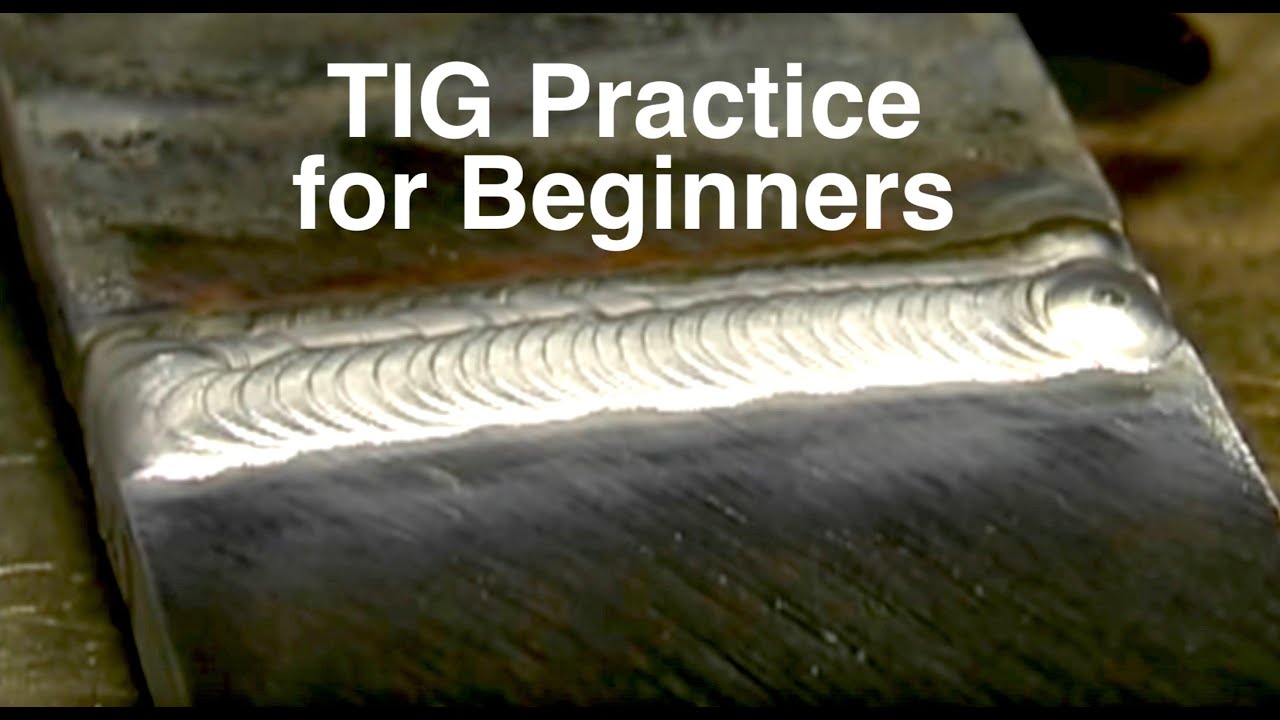

Step 3: Start Welding

With the metal prepared and the TIG welding machine set up, it’s time to start welding. Position the torch at a 10-15 degree angle from the workpiece and hold it steady. Start the arc by gently tapping the tungsten electrode on the metal surface, creating a small spark.

Once the arc is established, begin moving the torch in a controlled motion along the joint, maintaining a consistent arc length and speed. Use both hands to guide the torch, ensuring stability and precision. Add filler wire as needed by dipping it into the molten weld pool.

Step 4: Complete the Weld

Continue welding the joint until you have achieved the desired length. Pay attention to maintaining a consistent weld pool and preventing any gaps or inconsistencies. Once the welding is complete, gradually reduce the amperage and allow the weld to cool naturally. Do not touch the weld immediately after welding, as it will be extremely hot.

Inspect the weld for any defects or imperfections. If necessary, use a grinder or other tools to smooth out any rough edges or excess spatter. A clean, well-executed weld will ensure the strength and integrity of the joint.

Summary

TIG welding is a versatile process that allows for precise and high-quality welds. By following these step-by-step instructions, you can successfully weld metal using TIG welding techniques. Remember to prioritize safety at all times and practice proper preparation and technique for optimal results.

Frequently Asked Questions

Here are some commonly asked questions about how to weld metal with TIG welding:

What is TIG welding?

TIG welding, or tungsten inert gas welding, is a welding process that uses a non-consumable tungsten electrode to produce the weld. The electrode creates an electric arc with the base metal, which melts and fuses the metal together. TIG welding is known for its precision and ability to produce high-quality welds.

What materials can be welded with TIG welding?

TIG welding is suitable for welding a wide range of materials, including steel, stainless steel, aluminum, brass, and copper. It is commonly used in industries such as automotive, aerospace, and construction due to its versatility and ability to produce clean and strong welds.

What equipment do I need for TIG welding?

To perform TIG welding, you will need a TIG welding machine, a tungsten electrode, a welding torch, a gas supply (usually argon), and filler material (if needed). Additionally, you will need safety equipment such as welding gloves, a welding helmet, and protective clothing to ensure your safety during the welding process.

What are the advantages of TIG welding?

TIG welding offers several advantages over other welding processes. First, it produces high-quality, precise welds with minimal distortion. It also allows for greater control over the welding process, making it suitable for intricate welds and thin materials. Additionally, TIG welding can be used on a variety of metal types and provides excellent visibility of the weld pool, resulting in better weld bead appearance and overall quality.

What are some tips for successful TIG welding?

There are a few tips to keep in mind for successful TIG welding. Firstly, make sure to clean the base metal thoroughly before welding to remove any contaminants that may affect the quality of the weld. Secondly, maintain the correct angle and distance between the tungsten electrode and the workpiece to ensure a stable arc. It is also important to control the heat input by adjusting the amperage and travel speed appropriately. Lastly, practice proper welding techniques and maintain a steady hand for consistent and strong welds.

By following the step-by-step guide outlined in this article, individuals can begin their journey towards becoming proficient TIG welders. It is crucial to prioritize safety, invest in the right equipment, and master the techniques of striking an arc, maintaining proper torch angle, and controlling the welding puddle. With dedication and determination, one can unlock the vast potential of TIG welding, creating durable and visually appealing welds that stand the test of time. So, let’s embrace the art and science of TIG welding and continue to push the boundaries of what is possible in the world of metal fabrication.