Underwater Welding How Do It WorK ( AN EASY GUIDE)

what is underwater welding?

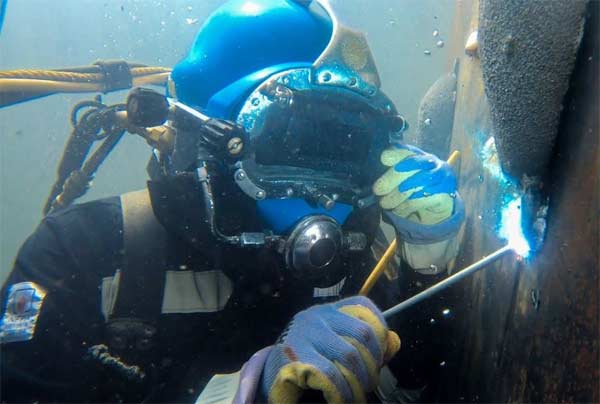

Do you know Underwater Welding How Do It Work? Underwater welding is the process of joining two metals (such as steel) underwater, with the use of an electric arc. It is done using protective clothing and equipment.

Underwater welders usually work in pairs so that one can protect the other from drowning. The most important piece of protection for underwater welders are a diving helmet and oxygen tank .these allow them to operate at depths where oxygen levels may drop below those found in ordinary atmospheric air (around 20% – 21%).

Underwater welding can be divided into two groups,

WIG welding –

WIG is also known as wet welding or submerged arc welding and operates with a flux core electrode in fresh or saltwater. In this process, the welder gets totally wet but does not have to be fully immersed.

As because of the design of an airtight helmet that is lowered over their head, supplying breathing air to them while also isolating them from the high pressures and cold environment of deep-sea diving.

SCUT welding –

SCUT stands for Submerged closed-arc washerless arc welding on plants that live entirely underwater. This process uses flux core rods that are completely submerged in water during operation instead of using an electric supply.

what is the pre-weld preperaion for underwater welding?

Underwater welding is an interesting job, and the process requires a lot of preparation before you even get to the actual welding. Underwater welding is used extensively in the oil and gas industry as well as in marine construction projects such as bridge building or shipbuilding.

When it comes to underwater welding, there are several things you need to look into before starting your work –

- Safety. Safety goggles, gloves, and chest waders are the first things an underwater welder is going to put on before starting work.

- Welding underwater will require a dry suit, mask, and hydraulic lines fed from the scuba pump.

- Wet welding suits may be used with limited functionality, but these can have issues with insulation if not used correctly or due to a leak in seams.

- the difference between wet and dry is in the need for cooling oil which flows into the sleeve/pant leg fabric of the suit via a suction hose.

- a baseline survey dive consisting of checking your hand-held torches or pistol grip torches for preheat condition and checking the integrity of the air supply, lines, and valves with no hose running

- surface has to be sufficiently clear of hydrogen sulfide gas from sewage outfalls about 6 feet away from under-water weld site.

Plasma cutting may require different additional control panels, but TIG arc welding does not as a welder is laying on an air compressor flat-plate surface area while torch head leads are connected to gas supply at the far end of the work site.

how do underwater welding electrodes differ from the surface?

As seen above, underwater welding is not just done differently due to the lack of air; it required different techniques and equipment.

As an underwater welder, one needs to make sure that the copper connectors and cables are specially designed for use in water. For instance, a gel may need to be used in order to reduce corrosion.

In addition, the arc welder must either work on a much lower current than is typical on land or have higher-density power cables so that it can transmit more current through its electrodes.

The electrodes used for underwater welding are smaller and more durable than the type of electrodes designed for use on the surface.

The smaller size means that it’s easier to ensure a good connection with the work because there is less room for error; while durability ensures that contact needs to be made from a short distance. The electrode can withstand immersion in water without breaking.

However, one downside is that you will need 20% more power when using underwater electrodes than with surface ones. Another downside may be time spent getting set up–it takes more time simply because of all of the equipment needed, accessories like gloves and mask, as well as finding an appropriate location. While laying lines on land seems much faster and easier than doing so underwater.

Underwater Welding How Does It Work?

Underwater welding is a form of metal arc welding, one of the most common and versatile methods in welding. The MIG or MAG process involves using an electric arc to burn a filler material (welding rod) at a high temperature, where it melts into the joint.

The welded metals are submerged in water to protect the air from being contaminated with weld spatter. This process allows the underwater welder to make repairs on various kinds of structures like bridges, ships and oil rigs marine structures offshore platforms, etc.

Underwater welders can lower project costs because they don’t have access to having to carry large amounts of steel beams for structural support underwater as well as painters on-site saving the company time and money.

Final words:

I hope you found this article informative and helpful. If you have any specific questions about welding or underwater welding, please don’t hesitate to contact us. We are always happy to provide more information on the topic!