Underwater Welding Equipment & Purpose

Today we discuss some basic Underwater Welding Equipment & Purpose. Have you ever seen someone welding underwater?

Welding is the process of joining two or more pieces of metal by heating them to a point where they can merge together. This can be done through a variety of methods, but one way is underwater welding.

There are many reasons why people may need to weld underwater. Sometimes it’s necessary because the object being welded is too large or heavy to move, or because it needs to be repaired in a difficult-to-reach place. In other cases, welding may be used for aesthetic reasons, like creating sculptures or adding details to a structure.

Whatever the reason, underwater welding presents unique challenges that must be overcome. In this post, we’ll explore the types of welding equipment used for underwater welding and their purposes. Keep reading to learn more!

5 Underwater Welding Equipment & Purpose

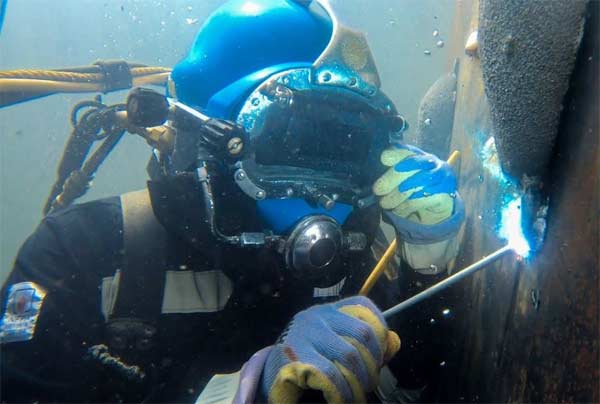

1. Underwater Diving helmet:

For the underwater welder, a diving helmet is a vital piece of equipment. This indispensable tool allows the welder to see clearly underwater and maintain a connection to the surface. There are many different types of diving helmets available on the market, each with its own set of advantages and disadvantages. In order to find the right helmet for your needs, it is important to understand the basics of what is available.

There are three main types of diving helmets: open circuit, closed circuit, and free-flow.

Open-circuit helmets use compressed air that is supplied by an external source. The open-circuit helmet is the simplest design and consists of a single air tank that is connected to the diver by a hose. This type of helmet allows divers to breathe normally from the atmosphere and does not require any other equipment such as an air compressor or regulator.

The semi-closed circuit helmet also has a single air tank, but it is connected to a second smaller tank that contains compressed gas specifically for the diver’s air supply. This type of helmet is popular with commercial divers as it allows them to share air supplies with their team members. They recycle exhaled air back into the system, which helps reduce the amount of air used.

The free-flow helmet is the most advanced design and uses a constant flow of compressed gas which is delivered directly to the diver’s lungs. This type of helmet does not require any hoses or tanks.

- Accessories

- Diving suit

- Electrodes

- Stinger

- Power supply