welding in a confined space: How to Safely weld in a tight space.

Today we discuss welding in a confined space. welding is an essential process in many industries. But, when welding in a confined space, it’s important to follow the safety guidelines that are set forth by the National Institute of Standards and Technology (NIST). These guidelines help protect workers and the environment. In order to safely weld in a tight space, you need to be aware of these safety tips.

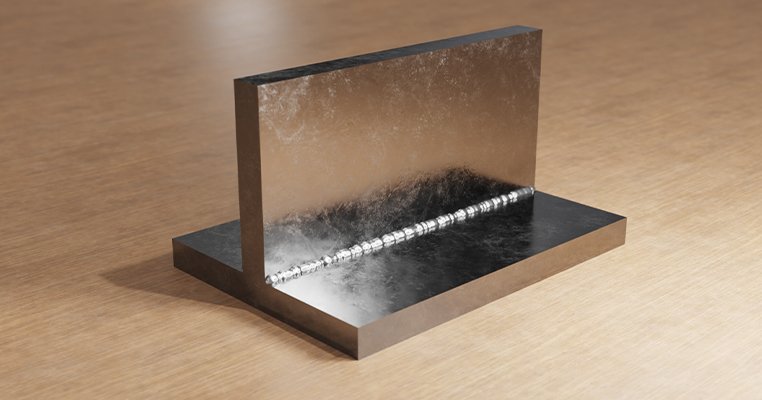

Use the correct welding equipment

When welding in a confined space, it’s important to use the proper equipment.

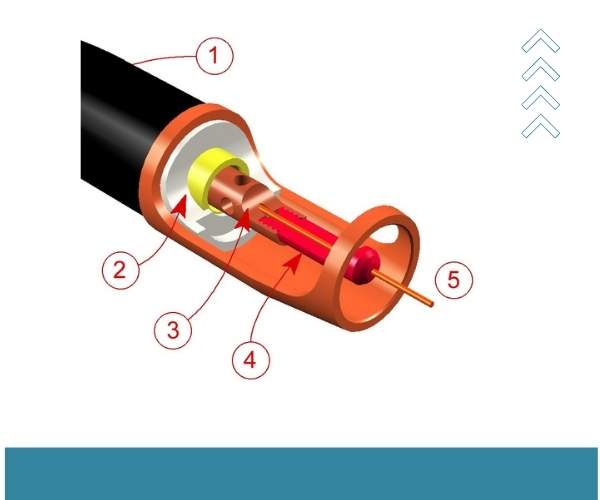

The equipment you choose is going to depend on your job and what material you are welding. For example, if you are going to be a welder tin in a confined space, you will need a gas-shielded arc welding torch.

This list will give you an idea of what types of materials and procedures are safe for this type of space.

Need to Know About Welding in a confined space

In order to weld in a confined space, it’s important to follow the safety guidelines that are set forth by the National Institute of Standards and Technology (NIST).

The first and most important tip is to protect your eyes from contact with molten metal.

Another safety precaution is staying alert at all times. Welding can be an intense process that requires concentration. If you become too tired, you could potentially lose focus and cause yourself serious injury when you least expect it.

Another thing that’s important when welding in a confined space is using the back of your shield as support while moving around the area where you’re welding. This helps keep balance and reduces the risk of falling on your backside.

How to Safely Weld in a Tight Space

In order to make sure you’re welding as safely as possible, it’s important to follow the guidelines set forth by NIST.

The first step is to be aware of the risks involved with welding in tight spaces. You need to know how much heat your weld produces and which parts of your body can be exposed. You also need to know that the equipment you have will have an impact on the safety measures you should take in a tight space.

The next step is to put proper protection on yourself and any machinery that might be used for welding in a tight space. This includes wearing gloves, goggles, and boots that are specifically designed for use in a confined space.

Follow the NIST Guidelines for Welding in a confined space

When welding in a confined space, it’s important to follow the safety guidelines set forth by the National Institute of Standards and Technology. When following these guidelines, you can ensure the safety of yourself and others around you. These guidelines help protect workers and the environment.

Welding in a confined space requires careful attention to detail to avoid accidents. Welders should wear eye protection that meets ANSI standards, safety glasses, or goggles. They should also wear ear protection that meets ANSI standards or plugs for both ears.

To prevent burning through materials in a confined space, welders should use only undersized electrodes (those less than 0.023 inches thick). For each thickness of electrode used, they need to add a layer of flux or wire at least 1/8 inch in diameter no closer than 2 inches to the workpiece and then make sure they keep any part that touches the workpiece at least 4 inches away from the workpiece while welding.

The material must be held down firmly enough so that it doesn’t lift up while welding on it with an electrolyte-containing gas shield gas (CFG) shielding gas (SFG).

Remove any obstacles before welding

Before welding, you must remove any obstacles in the area. Only one person should be welding at a time and they should be on the opposite side of the obstacle. This is to prevent any accidental contact with the hot metal.

Additionally, anyone near the work area needs to wear protective goggles and gloves that can withstand high heat. Welding sparks can cause serious injury if they hit unprotected skin or clothing.

Know the size of the space you are welding in

When welding, it’s important to know the size of the space you are in. This is because you have to be able to move around the space in order to get a good weld. You should also consider if there are any obstructions in your area, like pipes, wires, or other objects that could cause injury.

If you’re not sure what the size of the space is, measure it before you start welding. It’s also helpful to estimate how much room you need before you start welding.

For example, if you are working with a sheet metal fabrication company and they have an item they need you to bend in one spot, but it needs to be done on a tight deadline, then you should start by estimating how long it will take for your work.

If it turns out that bending only takes two hours and starts at 10 am, then 10 am would be the best time for this task.

Final words for welding in a confined space:

The NIST guidelines for safe welding in confined spaces are the best and only way to ensure the safety of your welding.

This guide will walk you through the steps to safely weld in a confined space.