3 Heat Welding Tools for Flooring

What is heat welding and how does it work

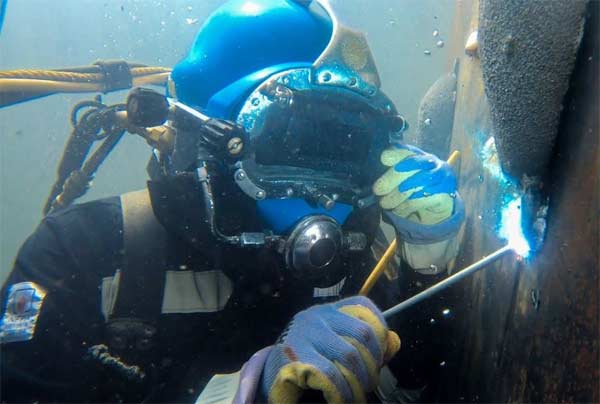

Heat welding is one of the oldest methods of joining materials, dating back to the time when metal was first discovered. It is used today in industries such as shipbuilding, automotive manufacturing, and construction.

Today we tell some about Heat Welding Tools for Flooring. Here two pieces of metal are joined together by melting the lower layer using an electric arc.

The heat energy from the melted lower layer flows through, or “welds” (hence “heat-welding”), to the upper layers and cools them down. This process can be done with a variety of metals but is most often used on carbon steel and stainless steel.

Heat welding has many applications because it can be quickly applied with minimal setup time. The heat level required to perform this type of welding varies depending on the materials being welded but typically ranges from 600 degrees Fahrenheit to 800 degrees Fahrenheit.

No products found.

Types of heat welds:

There are several different types of heat welds that can be done in a welding shop. One type is called arc welding, which is created by a welder with the use of an electric current.

Another type is called oxyfuel, which uses compressed oxygen and fuel gas to create the necessary flame for welding.

There’s also a tungsten inert gas (TIG) weld, where metal pieces are heated up until they melt and then filler material is added.

The final type of weld mentioned here is the flux core arc or FCAW, which uses a continuous wire feed system while simultaneously heating it up with an electric arc from one electrode to another when welding two pieces together.

Why use a heat welder for flooring:

A heat welder is a powerful tool that can be used for many different things. Let’s explore some reasons why you would want to weld the Heat Welding Tools for Flooring-

how to weld safety flooring:

there are some safety precautions to take before you start your project.

-never leave the welder unattended, so be sure someone is present in case an emergency situation occurs

-wear gloves and eye protection (a welding mask can help prevent splashes or sparks)

-keep all combustibles away from the welding area, including paper documents that could catch fire due to a spark

-“No smoking” signs should be posted at least 15 feet around this area as well as keeping any flammable liquids out of reach of open flames -you also want to wash up for 30 minutes after finishing with soap and water and check your work again before leaving it alone on its own.

heat weld gun:

No products found.vinyl welders:

No products found.how to heat weld vinyl flooring:

Vinyl flooring is an affordable, low-maintenance option for a variety of commercial and residential applications. One way to make vinyl look even more luxurious is by heating the seams together with a heat welder.

Heat welding vinyl floor requires some basic equipment and skills that are easy to learn, but it can be tricky if you haven’t done it before.

Installing vinyl flooring is easy as it can be glued down or heat welded on top of existing floors such as carpet, hardwood, or tile. Heat welding takes less time than gluing because you don’t have to wait for the glue to dry before walking on it.

You also don’t risk ruining the surface underneath with too much adhesive as you do with normal adhesives which could cause damage if left for too long before being walked on again.

how to heat weld vinyl fabric:

Heat welding vinyl fabric is an alternative way to sew a seam using the needle and thread. In some cases, heat sealing may be faster than sewing and can give a less bulky finish. You will need to purchase a heat welding tool for flooring – such as the Welder from GEFU.

Polycarbonate can be heat welded using the ICE-O WELL™. In order for polycarbonate sheeting and fabric to stick together, they require some sort of preheating. This makes it possible for designers with a limited budget who offers vinyl flooring that is longer than the width of their machine to create designs at least twice as wide as their machine parts.

The vinyl should be clean and free of dirt or excess water, which prevents any type of sealing from occurring when you’re welding the pieces together. A Paddle Heater Plate/Inner Tank (AC-HEAT) is used in this step, either separately on a cart or interconnected with another hot glue system

Turbo heat welding tools:

Turbo heat welding tools are a new innovation in the industry, providing a more efficient and economical method of joining materials. They have many advantages over traditional methods for the production of welds.

They are significantly faster and more cost-effective than other methods, making them an excellent choice for those looking to get the most out of their investment.

HWT is a fusion process that provides high-quality welds with minimal distortion to the base metal. This process has been used on everything from aerospace components to pipelines.

Sinclair heat welding tools:

Sinclair Heat Welding Tools for Flooring are designed to dry and seal the edges in one step. They offer an array of tools for welding all types of floor coverings. The Sinclair heat welding tools are used for installing natural stone flooring, porcelain tile, and carpet tiles without adhesive.

Founded in 1974 by Max Friedman, the company has grown from just 2 employees to approximately 100 with over 50 years of experience.

They offer a variety of different products such as the Model D bracket-installer that will ‘dab’ one-inch welds onto stone or ceramic tile; the Model C Flow-Weld system that will flow liquid resins into an open space or around corners; and Model T Poured hot liquid resin into joints between any square or rectangular shape

Crain heat welding tools:

CRAIN is one of the top suppliers of technical equipment in North America.CRAIN specializes in designing innovative and cost-effective solutions for optimal workability. They are used for flooring. They come in two types: side hammer and clamper.

For a side hammer, one long pipe is welded on the inside of the tool while another long pipe crosses it to form an “X” from which the grind discs or hammers hang. The welding process starts when a clamp-on bolted plate snapped into place around the pipeline flush with its ends and then clamped by both bolts at either end.

A clamper has only pulley handles designed for left and right-handed operation with either two or four chains. This is attached to them with H links holding them together operating independently on the high-pressure heated wire (HPHW).

CRAIN CHT2102A This portable unit is designed for use on architectural market panels up to six inches thick (.69 cm) like drywall, paneling, drywall joint compound, plywood, and paintable surfaces with or without plastic trim.

leister heat welding tools:

Leister Welding Tools has been employing heat welding tools for flooring since 1873 and they are a family-owned, privately held company.

A leister heat welding tool means for fastening together strips of flooring without the usual hammer and nail or other typical fasteners. Leister tools use an electric heating element to take normal metal seams (not unlike those used on sinks) and make them red-hot while simultaneously feeding material under it with a handsaw to affix materials at either side of the seam.

The products that Leister offers can be divided into open-flame equipment and hot wire welders. Open flame equipment is perfect for joining, repairing, or shaping by using an operating gas supply with an air-fuel ratio set to 1:1.

Winkelman heat welding tools:

Founded in 2003, Foe Winkelman has quickly become the leading manufacturer of innovative user-friendly heat welding tools. There are a variety of sizes and textures of Foe Winkelman welding rods. They come in 3 different diameters, 2.5mm, 3mm, and 4mm. All the rods on this page are stick-length for use with electricity, gas, or oxyfuel.

vinyl floor welding rod:

Drawbacks of using a heat welder for flooring:

Conclusion:

As you can see, there are many types of heat welding tools for flooring and heating that will help make your project easier. These tools for flooring are a great way to save time and money. We hope this article has helped you learn about the benefits of heat welding tools for flooring. If not, please feel free to reach out and we will be more than happy to help!