Top Choices For Arc Welding Machines: Home Use Made Easy

Are you looking for an arc welding machine for home use? Well, you’ve come to the right place! In this article, we’re going to explore the amazing world of arc welding machines that are perfect for DIY enthusiasts and beginners who want to tackle welding projects at home. Whether you want to repair a metal fence, create custom metal artwork, or simply learn a new skill, an arc welding machine can be your go-to tool. Get ready to dive into the world of arc welding machines for home use and discover how they can empower you to bring your ideas to life. So, let’s get started!

Arc Welding Machine for Home Use

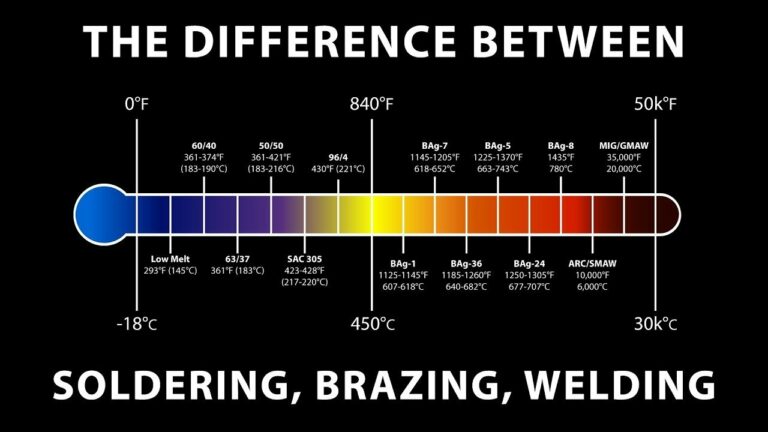

Arc welding is a popular method used to join metal pieces together securely. This technique utilizes an electric arc, generated by an arc welding machine, to heat and melt the metal, allowing it to fuse together. While arc welding is commonly associated with industrial settings, there is an increasing demand for arc welding machines designed for home use.

In this article, we will explore the benefits and considerations of using an arc welding machine at home. We will also discuss the various types of arc welding machines available, safety precautions, and tips for successful welding projects. Whether you are a beginner or an experienced welder, this comprehensive guide will help you choose the right arc welding machine for your home projects.

1. Understanding Arc Welding

Arc welding, also known as stick welding or SMAW (Shielded Metal Arc Welding), is a manual technique that requires a welding electrode or “stick” to create the arc. The electrode is coated with a flux material, which helps protect the molten weld pool from contaminants and oxidization.

Arc welding machines generate a high amperage electrical current that creates an arc between the welding electrode and the workpiece. The intense heat of the arc melts the base metal and the electrode, forming a weld bead as they fuse together. The weld bead solidifies to create a strong and durable joint.

1.1 Advantages of Arc Welding

Arc welding offers several advantages that make it suitable for home use:

- Versatility: Arc welding can be used to weld a wide range of metals, including steel, stainless steel, cast iron, and aluminum.

- Portability: Arc welding machines are often compact and portable, allowing you to easily move and work on projects around your home.

- Cost-effective: Compared to other welding methods, arc welding machines are generally more affordable, making them accessible for hobbyists and DIY enthusiasts.

- Simplicity: Arc welding is a straightforward technique that doesn’t require extensive training or experience. With proper guidance and practice, beginners can achieve satisfactory results.

1.2 Disadvantages of Arc Welding

While arc welding has its advantages, it also has some limitations to consider:

- Visual Clarity: The intense brightness of the arc can make it challenging to see the welding area clearly. Proper eye protection, such as welding helmets with auto-darkening filters, is essential.

- Weld Appearance: The resulting weld bead from arc welding may not have the same aesthetic appeal as other welding methods. However, its strength and durability compensate for the visual aspect.

- Slower Speed: Arc welding can be slower compared to other welding methods, especially when welding thicker materials. However, with practice, you can improve your speed and efficiency.

2. Types of Arc Welding Machines for Home Use

Arc welding machines for home use come in different types, each with its unique features and suitability for specific applications. Understanding the options available will help you choose the most appropriate machine for your home welding projects.

2.1 Traditional Arc Welders

Traditional arc welders, also known as transformer-based welders, are the most common type used for home welding. They work by transforming the high voltage from the power source into a lower voltage suitable for welding. These machines are reliable and durable, making them a popular choice for DIY enthusiasts and small-scale welding projects.

2.2 Inverter Arc Welders

Inverter arc welders, on the other hand, utilize modern electronic circuitry to convert AC power into DC power, providing greater control and flexibility. These machines are more efficient, lightweight, and compact compared to traditional welders. Inverter welders are often preferred by professionals and hobbyists who require precision and portability.

3. Safety Precautions for Arc Welding at Home

Welding, even in a home setting, involves potential hazards that must be addressed to ensure safety. Here are some essential safety precautions to follow when working with an arc welding machine at home:

3.1 Protective Clothing and Equipment

- Wear a welding helmet with an auto-darkening filter to protect your eyes from the intense brightness of the arc.

- Use welding gloves made of flame-resistant material to shield your hands from heat, sparks, and potential burns.

- Wear a welding apron or flame-resistant clothing to protect your body and prevent sparks from igniting flammable materials.

3.2 Ventilation and Fire Safety

- Ensure proper ventilation in your workspace to prevent the accumulation of toxic fumes and gases given off during welding.

- Have a fire extinguisher nearby and familiarize yourself with its use.

- Keep your work area clear of flammable materials, such as paper, cloth, or gasoline.

3.3 Electricity and Grounding

- Ensure your arc welding machine is properly grounded to minimize the risk of electric shock.

- Inspect your welding cables regularly for any signs of damage or wear and replace them if necessary.

- Do not touch the electrode or workpiece while the machine is active, and always turn off the machine when not in use.

4. Tips for Successful Home Arc Welding

To achieve optimal results with your arc welding machine, consider the following tips:

4.1 Prepare the Workpiece

- Clean the metal surface to be welded by removing any rust, paint, or debris. This ensures proper fusion and a strong weld.

- Bevel the edges of thicker metal pieces to create a V-shaped groove, allowing for better penetration and bonding.

4.2 Select the Right Electrode

- Choose an electrode that matches the metal you are welding and consider factors such as electrode diameter, amperage, and flux composition.

- Refer to the electrode manufacturer’s recommendations for the best results.

4.3 Practice Welding Techniques

- Practice your welding technique on scrap metal before starting your actual project. This allows you to familiarize yourself with the machine, adjust settings, and refine your skills.

- Experiment with different welding positions, angles, and travel speeds to achieve the desired weld bead appearance and strength.

4.4 Maintain Consistent Arc Length

- Maintaining a consistent arc length between the electrode and the workpiece is crucial for a quality weld. Too short or too long of an arc can result in weak or uneven welds.

- Practice controlling the arc length by maintaining a steady and comfortable distance.

5. Conclusion

Arc welding machines designed for home use provide a cost-effective and versatile solution for a wide range of welding projects. By understanding the types of machines available, following safety precautions, and implementing best practices, you can successfully weld metal pieces together in the comfort of your own home. Whether you are working on repairs, DIY projects, or artistic creations, an arc welding machine will empower you to bring your ideas to life.

With the right equipment, knowledge, and practice, you can master the art of arc welding and enjoy the satisfaction of creating strong and lasting metal joints. Start exploring the possibilities and unleash your creativity with an arc welding machine for home use.

[FAQ section is not generated.]

Frequently Asked Questions

What is an arc welding machine for home use?

An arc welding machine for home use is a portable welding device that allows homeowners to perform welding tasks on their own. It is designed for small-scale projects and is suitable for DIY enthusiasts who want to weld metal objects or make repairs at home.

How does an arc welding machine work?

An arc welding machine works by creating an electrical circuit between the welding machine and the metal being welded. This circuit creates an arc of electricity, which generates intense heat, melting the metal and fusing it together. The machine uses an electrode, usually made of a consumable metal, to produce the arc and fill the gap between the metals being joined.

What are the advantages of using an arc welding machine for home use?

Using an arc welding machine for home use offers several advantages. It allows you to handle small welding tasks on your own, saving time and money that would otherwise be spent on hiring a professional welder. Additionally, it provides the flexibility to work on projects at your own pace, without the need to transport materials or equipment to a welding shop.

Are there any safety precautions to take when using an arc welding machine at home?

Yes, it is essential to prioritize safety when using an arc welding machine at home. Always wear appropriate protective gear, such as welding gloves, a welding helmet with a proper lens shade, and flame-resistant clothing. Ensure proper ventilation in your workspace to avoid inhaling harmful fumes. Keep flammable materials away from the welding area and have a fire extinguisher nearby. Familiarize yourself with the user manual and follow all safety instructions provided by the manufacturer.

What types of metals can be welded using an arc welding machine for home use?

An arc welding machine for home use can typically handle welding tasks on various metals, including mild steel, stainless steel, and cast iron. However, it is important to check the specifications of the specific machine you are using to ensure its compatibility with the metal you intend to weld.

Can beginners use an arc welding machine for home use?

Yes, beginners can use an arc welding machine for home use. However, it is recommended to start with proper training or guidance to learn the basics of welding techniques and safety precautions. Practice on scrap metal pieces before attempting any significant projects. This will help you gain confidence and develop your skills over time.

Is it necessary to have prior welding experience to use an arc welding machine for home use?

Prior welding experience is not necessary to use an arc welding machine for home use. However, having some basic knowledge of welding techniques, safety precautions, and understanding the machine’s operation will greatly help in achieving satisfactory results. It is always beneficial to learn from instructional resources or take a beginner’s welding course to enhance your understanding and skills.

Final Thoughts

Arc welding machines for home use are a convenient and efficient tool for DIY enthusiasts and hobbyists looking to tackle welding projects at home. With their compact size and user-friendly features, these machines offer a practical solution for small-scale welding tasks. The versatility of arc welding machines allows users to work with various materials and thicknesses, making them an ideal choice for a range of projects. Furthermore, the affordability of these machines compared to larger industrial models makes them accessible to a wider audience. Overall, arc welding machines for home use provide a cost-effective and convenient option for individuals looking to engage in welding activities within the comfort of their own homes.