copper welding tool-need to know everything

Today we discuss copper welding tool. Do you need to know everything about copper welding tools before starting? If so, read on! In this blog post, we’ll introduce you to the most important things you need to know about copper welding tools before starting. We’ll also give you some tips on how to use these tools successfully.

What is copper welding?

Copper welding has many benefits, such as its ability to join metals at high temperatures. Another benefit is that copper welding can be used on most types of materials, including non-ferrous metals, plastics, and even glass.

The versatility of copper welding makes this process ideal for repairing broken objects around your homes like pots and pans, toys, or furniture.

Different types of copper welding tools?

Copper welding tools are easy to use and make a great alternative to more expensive products. However, there are some important things to consider before you invest in copper welding tools.

One of the most important aspects of copper welding tools is the type of copper used in their construction. There are three main types that you’ll need to know about before you purchase:

TIG (tungsten inert gas) – This process utilizes tungsten as the filler metal. It offers a high-quality weld and is usually quite expensive.

Flux-cored arc – This process uses fluxes that can be liquid or powder forms. These provide for a good weld but require additional upkeep as well as specific training for the user.

Gas Argon Arc – This process uses argon gas and has been associated with poor quality welds due to oxidation issues over time. However, this process offers versatility and ease of use when compared to other processes like TIG or flux-cored arc.

How to use a copper welding tool properly?

Copper is a very versatile material, which means it can be used in many different applications. One common use of copper is as a welding component. If you are not familiar with how to use copper welding tools, you should know the following things before making any decisions:

1) Copper can only be welded by electricity. This means that it is not capable of being welded by other methods, like gas or arc welding.

2) The type of electrode you will need depends on the application you are going to be using. There are two types of electrodes that work in copper: tungsten and a hard-drawn wire or rod.

3) Different materials require different temperatures for best results. You will have to find out which temperature your application requires before starting to perform the task properly and safely.

4) The thickness of your copper material needs to be taken into account as well when using copper for welding applications. You will need to find out what thickness your material needs for the proper strength and composition for successful welding results.

Tips for successful copper welding.

Whether you’re a beginner, intermediate, or expert with copper welding tools, there are some things that you can do to get the best results when using these tools.

Here are three tips to help make your copper welding more successful:

-Don’t always trust the tool manufacturer’s recommendations. There are many variables that can affect the quality of your work without any input from the manufacturer.

-Choose a position for your torch that provides the best light and air supply. If you’re doing a small job in tight quarters, it may be difficult to get all of your equipment in place but if you take care of the basics then you’ll still be able to produce professional-looking welds.

-Practice! It’s impossible to know what you don’t know until you’ve tried it out for yourself.

How do copper welding tools work?

When it comes to copper welding tools, it’s important to know how the tool works.

Copper is a great conductor and is used in soldering and brazing. Copper welding tools heat up the metal, which creates a fusing process that results in the removal of impurities and the creation of a solid weld. The most commonly used tool by professional welders is called a stick electrode, which uses an electric current to heat up the tip of the electrode so that it can transfer heat towards the base quickly.

A stick electrode can also be used as an arc flattener or an induction welder. For these applications, there are alternative types of electrodes that are more suitable for either application.

What are copper welding tools?

Copper is a great metal to use when you want your welding process to be aesthetically pleasing. It’s malleable and can accept a variety of shapes and designs.

It’s also a non-magnetic metal, which makes it perfect for welding with other metals. Copper is a natural conductor of electricity, so it doesn’t have any problems with heat or sparks.

Most copper welding tools are made of copper wire, but they can also come in the form of rolled stainless steel wire or solid copper wire. Copper welding wires are typically rated by diameter in the range of 0.030 to 0.035 inches.

benefits of using copper welding tools

Copper is a low-cost alloy that is easy to work with and has a great balance of properties. You can use copper welding tools to create welds that are strong and reliable, while also being affordable.

Welding with copper can reduce the need for other materials like steel, which are often more expensive and require more steps to produce. This saves you money and time, as well as reducing your environmental footprint. Copper is also highly resistant to corrosion, which means it’s easier to maintain than other materials.

Copper welding tools are also lightweight and durable. They don’t rust like steel does, so they’re easy to transport from place to place without worrying about them getting damaged or deformed during transit.

Another benefit of using copper welding tools is that they’re safer for your work environment than steel or even aluminum welding equipment. Although they have the same weight as these metals, they still have a lower risk of causing injury or even death in the event of an accident due to their lighter weight and lower melting point.

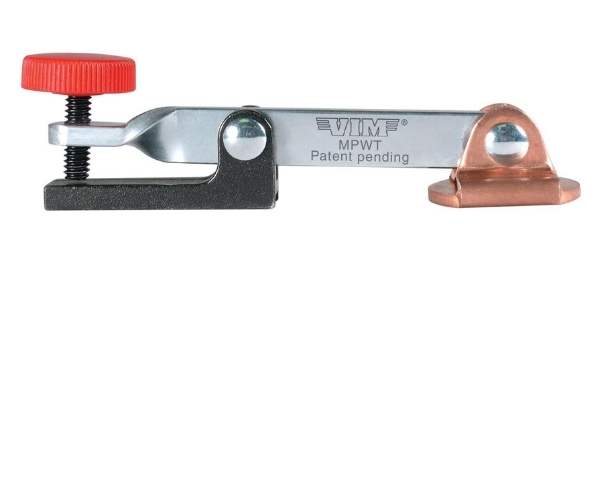

copper magnetic welding tool:

A copper magnetic welding tool is a special type of welder’s torch that uses magnets to hold the workpiece in place while the welder welds. Copper magnetic welding tools are used for welding metals such as steel, aluminum, and brass.

copper welding tool vs copper magnetic welding tool:

- Copper welding tool is a type of welding tool that uses copper wire to weld metal.

- Copper magnetic welding tool is a type of welding tool that uses magnets to weld metal.

- Copper welding tool is used to weld copper pipe.

- Copper magnetic welding tool is used to weld copper pipe and steel

Conclusion

Copper welding tools are a popular tool to use in certain types of welding. They can be used with any type of metal and create a solid weld due to a reaction with the metal, creating a strong bond. It is important to remember to use the right type of copper welding tool for the job.