How To Weld Galvanized Metal

Today we discuss How To Weld Galvanized Metal. In the world of metalworking, few materials are as versatile and widely used as galvanized metal. From construction projects to automotive repairs, the durability and corrosion resistance of galvanized metal make it an ideal choice for a wide range of applications.

However, when it comes to welding galvanized metal, there are some unique challenges that must be overcome. In this comprehensive guide, we will delve into the intricacies of welding galvanized metal, providing valuable insights and techniques to help you achieve strong and reliable welds on this particular material.

Whether you are a seasoned welder or just starting out on your journey, learning how to weld galvanized metal is an essential skill that can open up new opportunities in the field of metalworking. Throughout this guide, we will explore the key considerations to keep in mind when working with galvanized metal, including preparing the surface, selecting the appropriate welding method, and ensuring the safety of both yourself and your work environment.

With step-by-step instructions and expert tips, you will gain the knowledge and confidence needed to tackle welding projects involving galvanized metal with precision and professionalism. So, let’s dive in and uncover the secrets to mastering the art of welding galvanized metal.

How to Weld Galvanized Metal:

- Prepare your work area by ensuring good ventilation and wearing appropriate safety gear.

- Clean the galvanized metal using a wire brush to remove any dirt or debris.

- Preheat the metal using a propane torch to burn off the galvanized coating.

- Set up your welding equipment and choose the appropriate welding method for your project.

- Weld the galvanized metal using proper welding techniques and ensuring good penetration.

- Allow the metal to cool down slowly to prevent cracking.

- Inspect the weld for any imperfections and make necessary repairs if needed.

How to Weld Galvanized Metal:

Welding galvanized metal can be a challenging task due to the presence of zinc coating, which can release toxic fumes when heated. However, with the right precautions and techniques, you can successfully weld galvanized metal. In this article, we will guide you through the step-by-step process of welding galvanized metal, ensuring a safe and effective welding experience.

Step 1: Safety Precautions

Before starting the welding process, it is crucial to prioritize your safety. Ensure you have the following protective gear:

- Welding helmet with a dark shade lens

- Welding gloves

- Fire-resistant clothing

- Respirator mask

Additionally, work in a well-ventilated area or use a fume extraction system to minimize exposure to the toxic fumes released during welding. It is also advisable to have a fire extinguisher nearby in case of emergencies.

Step 2: Surface Preparation

Proper surface preparation is essential for successful welding. Follow these steps:

- Remove any dirt, oil, or grease from the galvanized metal surface using a degreaser or a wire brush.

- Use a grinder or sandpaper to remove the zinc coating from the area where the weld will be performed. This process is known as “scraping” or “grinding off” the galvanized layer.

- Clean the surface again to remove any remaining debris.

By removing the zinc coating, you ensure a clean welding surface and minimize the release of toxic fumes during welding.

Step 3: Choose the Right Welding Technique

When welding galvanized metal, it is recommended to use the MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding techniques. These techniques provide better control and reduce the risk of overheating the zinc coating. Follow these guidelines:

- Set the welding machine to the appropriate settings for the metal thickness and desired weld type.

- Use a welding wire specifically designed for galvanized metal.

- Keep the welding speed steady to avoid excessive heat buildup.

Welding galvanized metal requires patience and precision. Take your time to ensure a strong weld without compromising the integrity of the zinc coating.

Step 4: Post-Welding Treatment

Once you have completed the welding process, it is essential to perform post-welding treatment to protect the weld joint and restore the zinc coating. Follow these steps:

- Allow the welded metal to cool down naturally.

- Use a wire brush or sandpaper to smooth out any rough surfaces or spatter.

- Apply a zinc-rich paint or galvanizing spray to the weld joint and surrounding area. This will help prevent corrosion and restore the protective zinc coating.

By performing post-welding treatment, you ensure the longevity and durability of the weld joint while maintaining the protective properties of the galvanized metal.

Faqs for How To Weld Galvanized Metal:

Answer:

Galvanized metal refers to steel or iron that has been coated with a layer of zinc to protect it from corrosion.

This process, known as galvanization, involves immersing the metal in a bath of molten zinc, which creates a protective layer on its surface.

Galvanized metal is commonly used in outdoor structures, such as fences, gates, and metal roofs, due to its enhanced durability and resistance to rust.

However, when welding galvanized metal, special precautions need to be taken to ensure a safe and effective welding process.

Answer:

Yes, you can weld galvanized metal. However, welding galvanized metal requires some additional steps and safety measures due to the presence of the zinc coating. When heated, zinc produces fumes that can be harmful if inhaled.

Therefore, it is essential to take proper ventilation measures, such as working in a well-ventilated area or using local exhaust ventilation systems, to minimize exposure to these fumes.

Answer:

There are several methods to remove the zinc coating from galvanized metal before welding. One common method is mechanical removal, which involves using a wire brush, grinder, or sandpaper to physically scrape off the zinc layer from the area where the weld will be performed. This method is effective but can be time-consuming, especially for large or intricate pieces.

Another method is chemical removal, which uses a specialized solution or acid to dissolve the zinc coating. It is important to follow the manufacturer’s instructions and safety precautions when using chemical solutions, as they can be corrosive and harmful if mishandled. After removing the zinc coating, it is crucial to clean the surface thoroughly to ensure proper weld quality.

Answer:

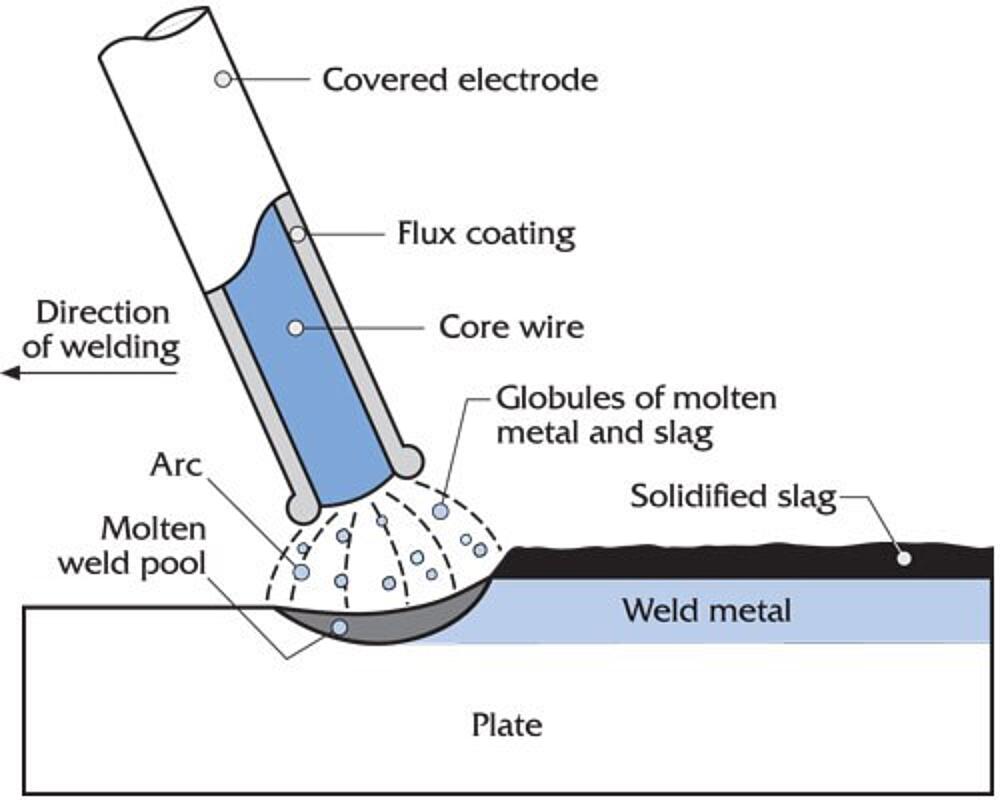

Different welding processes can be used for galvanized metal, but some are more suitable than others. Among the commonly used welding methods, metal inert gas (MIG) welding and stick welding (shielded metal arc welding) are often preferred for welding galvanized metal.

MIG welding utilizes a continuous wire electrode and an inert gas shield to protect the weld from contamination. It offers good control, and high welding speeds, and can handle a variety of thicknesses.

Stick welding, on the other hand, uses a consumable electrode coated in flux, which creates a protective shield during the welding process. It is a versatile and widely available method, suitable for outdoor applications.

Answer:

Yes, there are specific safety considerations when welding galvanized metal. As mentioned earlier, the zinc coating produces fumes when heated, which can be harmful if inhaled. Therefore, it is crucial to wear appropriate personal protective equipment (PPE), including a respirator with a particulate filter, to protect against these fumes.

Furthermore, proper ventilation is essential to ensure the removal of fumes from the work area. If working indoors, it is recommended to use local exhaust ventilation systems or set up fans to blow the fumes away from the welder.

conclusion:

learning how to weld galvanized metal is a valuable skill that can open up a world of possibilities in various industries. Although the process may seem daunting at first, the key is to approach it with patience, practice, and a commitment to safety. By following the proper techniques and precautions, welders can achieve strong and durable welds on galvanized metal, ensuring the integrity and longevity of their projects.

As with any skill, mastery comes with experience. So, don’t be discouraged if your first attempts don’t yield perfect results. Keep refining your technique, seeking guidance from experts, and staying up to date with the latest industry advancements.

With time and dedication, you will become proficient in welding galvanized metal, expanding your opportunities and contributing to the success of countless projects. So, grab your welding helmet, put on your gloves, and embark on this exciting journey of mastering the art of welding galvanized metal – the possibilities are endless!