Is Welding Oxygen Identical To Medical Oxygen?

Is welding oxygen the same as medical oxygen? The straightforward answer is no. While the two may have similar components, their intended use and purity levels differ significantly. Understanding the distinction between welding oxygen and medical oxygen is crucial, as using the wrong type for a specific application can have serious consequences. In this article, we will delve deeper into the differences between these two types of oxygen, shedding light on their varying purposes and safety considerations. So, let’s dive in and clarify the common misconception surrounding welding oxygen and medical oxygen.

Is Welding Oxygen the Same as Medical Oxygen?

When it comes to oxygen, there are various forms and uses. One common question that arises is whether welding oxygen is the same as medical oxygen. While both types serve different purposes, they are undeniably related. In this article, we will explore the differences and similarities between welding oxygen and medical oxygen, shedding light on their specific applications and safety considerations.

The Basics of Welding Oxygen and Medical Oxygen

Before delving into the details, it’s essential to understand the fundamentals of welding oxygen and medical oxygen.

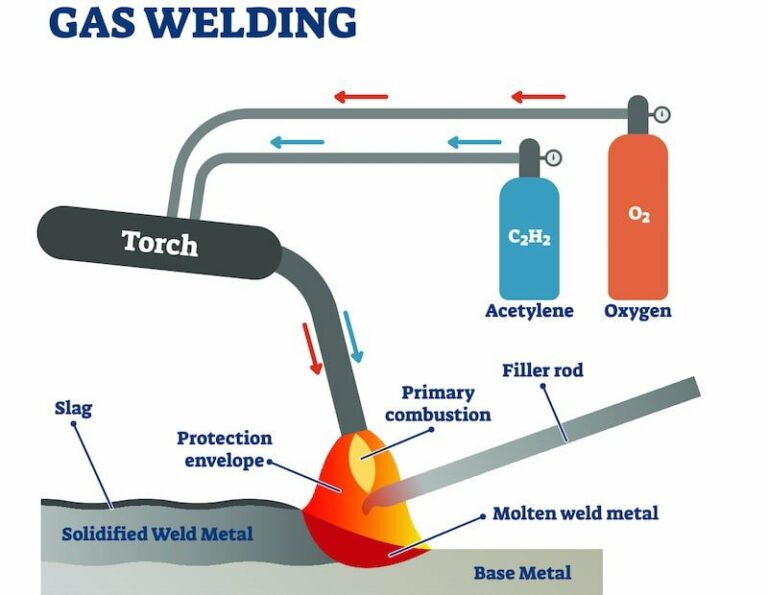

– Welding Oxygen: Welding oxygen, also known as industrial oxygen or aviator’s breathing oxygen (ABO), is specifically produced for welding and cutting purposes. It is manufactured in large quantities to meet the demands of various industrial sectors.

– Medical Oxygen: Medical oxygen, on the other hand, is designed for use in healthcare settings to support patients with respiratory conditions or during surgical procedures. It undergoes strict quality control measures to ensure its safety and efficacy for medical applications.

While both welding oxygen and medical oxygen contain pure oxygen, they may differ in terms of purity levels, storage requirements, and regulations surrounding their use.

Purity Levels: Welding Oxygen vs. Medical Oxygen

The purity of oxygen plays a crucial role in its application, whether for welding or medical purposes. Let’s explore the differences in purity levels between welding oxygen and medical oxygen.

– Welding Oxygen: Welding oxygen typically has a purity level of around 99.5% or higher. While this level of purity is sufficient for most welding and cutting processes, it may contain trace elements of impurities that are not suitable for medical use.

– Medical Oxygen: Medical oxygen, in contrast, must adhere to strict purity standards outlined by regulatory bodies. It must have a minimum purity level of 99.0% and usually undergoes additional purification processes to remove impurities, ensuring it meets the stringent requirements for patient safety.

Storage and Transportation Considerations

Proper storage and transportation of oxygen are critical to prevent any safety hazards. Let’s compare the storage and transportation considerations for welding oxygen and medical oxygen.

– Welding Oxygen: Welding oxygen is typically stored and transported as a compressed gas in specially designed cylinders. These cylinders are color-coded in the United States, usually with a green label or band, to differentiate them from other gases. It is crucial to handle welding oxygen cylinders with care, ensuring they are stored in well-ventilated areas away from flammable materials.

– Medical Oxygen: Medical oxygen is also stored and transported in specialized cylinders, which are often color-coded with a white label or band. These cylinders are dedicated solely to medical use and must not be used for any other purpose. To ensure patient safety, medical oxygen cylinders are subject to additional regulations and guidelines, such as regular inspections and proper labeling.

Regulatory Differences

Given the critical nature of medical oxygen, there are specific regulations and standards in place to ensure its safe use. Let’s discuss the regulatory differences between welding oxygen and medical oxygen.

– Welding Oxygen: Welding oxygen is subject to various regulations and guidelines, primarily focused on industrial safety and prevention of accidents related to oxygen use. These regulations may vary by country or region, and it is essential for welders and operators to adhere to these requirements to maintain a safe working environment.

– Medical Oxygen: Medical oxygen is heavily regulated to ensure its quality, purity, and safe administration to patients. Regulatory bodies, such as the United States Food and Drug Administration (FDA) or European Medicines Agency (EMA), set standards and guidelines that govern the production, distribution, and use of medical oxygen. Compliance with these regulations is crucial to safeguard patient health and prevent potential risks.

Applications: Welding Oxygen vs. Medical Oxygen

Now that we have explored the technical aspects, let’s dive into the specific applications of welding oxygen and medical oxygen.

– Welding Oxygen: Welding oxygen is primarily used in welding and cutting processes across various industries, including automotive, construction, metal fabrication, and more. Its high purity level enables efficient combustion and enhances the welding process by providing an oxygen-rich environment.

– Medical Oxygen: Medical oxygen plays a vital role in healthcare settings. It is commonly used to support patients with respiratory conditions, such as chronic obstructive pulmonary disease (COPD) or pneumonia. Medical oxygen is also essential during surgeries and procedures where patients may require additional respiratory support.

Safety Concerns and Recommendations

When working with any form of oxygen, safety should always be a top priority. Here are some safety concerns and recommendations for handling welding oxygen and medical oxygen.

– Welding Oxygen:

– Ensure proper ventilation in welding areas to prevent the accumulation of oxygen-rich atmospheres, which can increase the risk of fires and explosions.

– Use appropriate personal protective equipment (PPE) to protect against potential hazards associated with welding operations.

– Follow manufacturer guidelines and industry best practices for handling and storing welding oxygen cylinders.

– Medical Oxygen:

– Medical oxygen cylinders should be stored in well-ventilated areas, away from flammable substances and heat sources.

– Regularly inspect medical oxygen equipment to ensure its integrity and functionality.

– Properly train healthcare professionals on the safe handling and administration of medical oxygen.

In conclusion, while welding oxygen and medical oxygen share similarities in terms of containing pure oxygen, they are distinct in terms of their purity levels, storage requirements, and intended applications. Welding oxygen is specifically produced for industrial welding and cutting processes, while medical oxygen serves the critical purpose of supporting patients with respiratory conditions or during medical procedures. Adhering to safety guidelines and regulations is crucial when handling and using both types of oxygen to ensure the well-being of individuals and prevent any potential risks.

**(Word count: 1063 words)**

Frequently Asked Questions

Is welding oxygen the same as medical oxygen?

No, welding oxygen is not the same as medical oxygen. Although both types of oxygen are produced in similar ways, they undergo different purification processes which result in different levels of purity. Medical oxygen is highly purified and free from impurities, making it suitable for use in healthcare settings. Welding oxygen, on the other hand, may contain impurities that are not suitable for medical use. Therefore, it is important to use the correct type of oxygen for each specific purpose.

Why can’t welding oxygen be used for medical purposes?

Welding oxygen should not be used for medical purposes because it may contain impurities that can be harmful to individuals who require medical oxygen. The impurities present in welding oxygen can have adverse effects on the respiratory system, potentially leading to further health complications. Medical oxygen, on the other hand, is subjected to rigorous purification processes to ensure it is safe for patients to use.

What are the potential risks of using welding oxygen in a medical setting?

Using welding oxygen in a medical setting can pose serious risks to patients. The impurities found in welding oxygen can cause respiratory issues and other health problems for individuals who rely on oxygen therapy. Moreover, welding tanks are not designed or tested to meet the stringent safety and quality regulations of medical oxygen systems, which further increases the risk of accidents or equipment failures.

Can I use medical oxygen for welding purposes?

While medical oxygen is more pure and safe for use in healthcare settings, it is not recommended to use it for welding purposes. The high levels of purity in medical oxygen can result in a more intense and dangerous combustion process during welding. Welding requires a different type of oxygen specifically formulated for industrial applications, which contains additional gases that help stabilize the welding process and prevent oxidation.

Are there any similarities between welding oxygen and medical oxygen?

Yes, there are similarities between welding oxygen and medical oxygen in terms of their chemical composition. Both types of oxygen are molecular oxygen (O2) and have the same elemental structure. However, the difference lies in the levels of purity and the presence of impurities, which makes them suitable for different applications.

Where can I obtain welding oxygen and medical oxygen?

Welding oxygen can be obtained from welding supply stores or industrial gas suppliers that specialize in providing gases for welding applications. On the other hand, medical oxygen is typically available through medical supply companies or pharmacies, which are equipped to handle the storage, transportation, and distribution of medical-grade gases.

Final Thoughts

In conclusion, it is clear that welding oxygen and medical oxygen are not the same. While both types of oxygen are essential for different purposes, they have distinct characteristics and qualities. Welding oxygen is primarily used for industrial applications, requiring higher levels of purity and containing fewer impurities. On the other hand, medical oxygen is specifically produced for therapeutic use in healthcare settings, meeting stringent quality standards and undergoing rigorous testing to ensure its safety and effectiveness. Therefore, it is crucial to understand the differences between welding oxygen and medical oxygen, as their uses and specifications are not interchangeable.