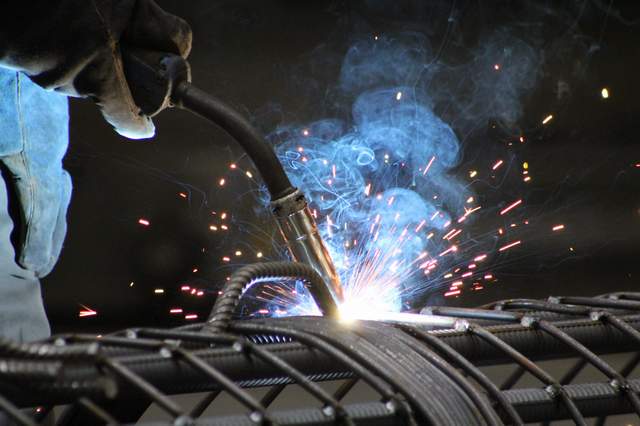

Mig welding advantages and disadvantages

today we discuss Mig welding advantages and disadvantages. Mig welding is a popular method of welding. It is also known as GMAW ie Gas metal arc welding. It is a versatile method of joining complex metals very easily. But Mig welding’s advantages and disadvantages depending on the nature of the job you are going to do. So it is quite natural to have a plan for what it will be used to accomplish.

Generally, MIG welders come with single to 3 phases. A single-phase MIG welder 110 or 230 volt is generally used in small shops, home garages, art shops, and body shops.

These MIG welders present a little bit of extra versatility for welding. The 1-3 phase MIG welder can also do the same thing as the single-phase welder.

You can easily classify the good and bad things of MIG welding after you clearly decide the type of work you do with the MIG welder.

MIG Welding Advantages

Easy to learn:

Mig welding is the easiest welding technique to learn. Any newbie can learn it within a week. It only needs adequate training and a little endurance to deliver a great weld in MIG Welding. Some people learn it only by following the guidelines provided by professionals.

Versatile welding:

Lots of professional welder love mig welding just because they can weld a variety of metals like steel, aluminum, mild thicker metals, etc without any hassle. Honestly saying it takes a little time to complete a welding task and is cost-efficient also.

High Productivity:

The MIG welding method gives high productivity to professionals because there is no changing of rods or brushing the rod repeatedly like another welding. This means it requires less repair and maintenance to supervise. Mig welders can also do their job in different positions to deliver accurate welding by a MIG welder.

Clean welding:

Mig welding requires less cleaning since it uses shielded gas to protect the arc. There is a very small chance to waste the alloying parts because the metal transfers throughout the arc. Generally, Mig welding produces less smoke and there are not any slags wanted to be chipped off.

Flexible welding Settings:

Another good advantage of MIG welding is the flexibility of welder settings to operate your welding for specific things. Suppose if you want to weld more plane materials, you can slow down the wire speed which will produce more arc.

Slower wire speed produces plane weld with deeper penetration and less spatter. Contrarily, if you want to weld thin materials, you can turn down the amperage to minimize the heat. A lower amperage setting helps to weld thinner materials.

Popularity:

If you take a look at small shops or car shops, most of them are using Mig welders because they are faster than other welding methods.

MIG Welding Disadvantages

Inappropriate for outdoor:

As you know that MIG welder uses shielded gas, it is not suitable for outdoor welding because the shielding gas needs to protect the purity to weld. For this, it is difficult to carry and not portable. In the case of windy weather, it would be hard to lay a good bead.

The Mig welder also needs a wire roll. Now there’s a method to mix your wire and shielding gas and that’s to make use of a flux-core wire. It is a wire that comprises a middle core of flux when burned will present a layer of safety very similar to a shielding gas.

Another thing is, a quality Mig welder like Hobart or lincoln generally weighs 65-70 pounds which is much heavier and difficult to move.

Expensive

Mig welding equipment price is higher and more complex compared to other welding devices. If any issue comes for repair or replacement, then it will cost more than you expect.

So before you purchase a MIG welding machine, make sure that you have a pre-idea about which one is perfect for you, its guarantee, and its longevity. Read this article before you make any purchases.

Limitations in position

The high mobility of the welding puddle and the high heat input indicates vertical and overhead welding. Whereas some welders would by no means even consider welding in these positions.

Limitations in welding

Mig welding doesn’t work nicely with rust, soiled surfaces, and paint. Another important thing to remember is, it cannot penetrate well into thick materials. Mig welding also needs much attention while welding.

Quick cooling rate

The welded metal will likely be cooled at rates that can be increased since they don’t seem to be coated by slag when the weld is accomplished.

Open arc process

Mig welding must be taken proper maintenance to protect the welder as it is an open arc method like other welding methods.

Conclusion

Lastly, you’ll understand all the advantages and disadvantages of MIG welders. The professionals are certainly further vital than a number of detrimental features of MIG welding devices. Apart from this, it clearly relies on consumer necessities and preferences of wielding. Hope this information helps you be taught the MIG welding advantages and disadvantages.