What is the difference between a cutting torch and welding torch?

Today we discuss the difference between a cutting torch and welding torch. A cutting torch is a tool that cuts through steel and other metals, while the welding torch melts the metal together. Both torches are typically used by welders, but depending on the project, they may be used interchangeably.

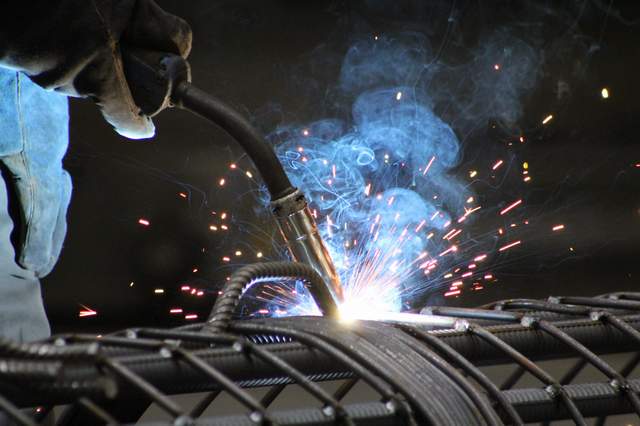

A cutting torch works differently than a welding torch because it actually cuts through objects instead of melting them to create new shapes. Cutting torches produce fire and sparks as they cut through metal to signify how effective they are.

welding torches:

Welding torches are an essential piece of equipment for any welder. They provide the heat necessary to fuse two pieces of metal together. There are many different types of welding torches available, so it is important to choose the right one for the job.

Here we will discuss the different types of welding torches and their uses. We will also look at some of the factors you should consider when choosing a welding torch. So, if you’re thinking about buying a welding torch, keep reading!

welding torches types:

One of the most popular tools in the welding industry is the welding torch. A welding torch provides heat for a wide range of tasks, including cutting, bending, and smoothing metal. There are many different types of torches, each with its own specific purpose.

The most common type of welding torch is an oxyacetylene welding torch.

Usage of welding torches:

The usage of welding torches has been a common practice in the industry for much longer than the general public realizes. In fact, the use of welding torches dates back to Assyrian times when they were used for metal casting. While the usage of welding torches has been around for many centuries, it is only recently that there has been a debate on how safe they are.

For the past century, welding torches have been used for a variety of different tasks. One of the most important uses has been to weld steel beams together in order to create buildings.

Cutting torch:

A cutting torch is a tool that uses heat and a controlled flame to cut through metal. The flame is produced by a fuel gas, such as acetylene, propane, or natural gas, and oxygen from an oxygen tank. The flame melts the metal, which is then forced out of the cut by the pressure of the gases.

If you are looking for a handheld welding tool that can easily cut through metal, you may want to consider investing in a cutting torch. a cutting torch can be used to quickly and easily cut through sheet metal, pipes, and other types of metals.

we will discuss the different types of cutting torches available on the market today, as well as provide some tips on how to use them safely and effectively.

Cutting torches types:

Cutting torches are tools that use heat to cut through metal. There are two main types of cutting torches: oxy-fuel and electric. The oxy-fuel torch uses oxygen and natural gas or propane to create a gas flame.

Electricity heats the tip of an electric cutting torch so it can cut steel, making the process much faster than an oxy-fuel torch. Both types of cutting torches usually use an oxygen regulator, cutting nozzle, fuel hose, and fuel tank to function properly.

Usage of Cutting torches:

Cutting torches are used for a number of different applications that require a high level of heat. The most common use of a cutting torch is metal welding, which requires a larger nozzle. Cutting torches use a stream of oxygen and fuel to produce intense heat and sparks at the end of the nozzle.

difference between a cutting torch and welding torch:

- Cutting torches are used to cut metal and other materials while welding torches are typically used for joining two pieces of material.

- Welding torches use a continuous flame while cutting torches have an intermittent arc.

- A gas-powered cutting torch uses propane or natural gas as fuel, whereas a welding torch is powered by electricity.

- Cutting torches have nozzles with adjustable flames, but welders have fixed-length nozzles.

- A cutting torch has a pointed nozzle while a welding torch has a rounded nozzle

- A cutting torch is a gas-fueled tool that burns at an extremely high temperature and can be dangerous if not handled properly.

- Welding torches use propane or natural gas fuel, which is easier to handle than a cutting torch because it doesn’t burn as hot.

- When using a welding torch, the flame should always be shielded from the operator with either an asbestos shield or another piece of shielding material so that the heat does not affect them.

- The type of fuel being used will also determine how long each canister lasts – propane has a longer life span than natural gas.

- The main difference between the two types of torch is that you can’t weld with a cutting torch because they don’t have enough heat output for this process.