How To Weld Metal Beads

Today we discuss How To Weld Metal Beads. Welding metal beads is a captivating process that allows you to transform ordinary pieces of metal into intricate and eye-catching designs. From jewelry making to decorative accents, the possibilities are endless when it comes to incorporating metal beads into your creations.

However, mastering this skill requires a combination of technical expertise and artistic flair. Throughout this guide, we will cover the essential tools and equipment needed, the different welding techniques involved, and provide valuable tips and tricks to ensure your welding journey is a successful one. So, gear up and prepare to embark on an exciting adventure as we unravel the secrets of welding metal beads!

How to Weld Metal Beads

Welding metal beads is a crucial skill for anyone working with metal fabrication. Whether you are a professional welder or a DIY enthusiast, knowing how to weld metal beads correctly can greatly improve the strength and durability of your projects. In this article, we will guide you through the step-by-step process of welding metal beads, from preparing the materials to achieving a clean and strong weld.

Step 1: Prepare the Materials

Before you begin welding, it is essential to gather all the necessary materials and ensure they are properly prepared. Start by selecting the appropriate welding machine for the job. Different metals may require different welding techniques, so choose a machine that suits the type of metal you are working with.

Next, gather the necessary safety equipment, such as welding gloves, a welding helmet, and a welding jacket, to protect yourself from sparks and heat. Finally, make sure your work area is clean, well-ventilated, and free from any flammable materials.

Once you have gathered your materials, clean the metal surfaces that will be welded. Use a wire brush or a grinder to remove any rust, paint, or debris. This will ensure a clean and strong weld by allowing the metal to fuse together properly.

Step 2: Set Up the Welding Machine

Now that your materials are prepared, it’s time to set up the welding machine. Start by connecting the machine to a power source and ensuring it is properly grounded.

Adjust the welding settings according to the type and thickness of the metal you are working with. Consult the manufacturer’s instructions or seek professional advice if you are unsure about the appropriate settings.

Next, select the appropriate welding electrode or wire for your project. Electrodes and wires come in different sizes and types, so choose the one that best suits your metal and welding technique.

Insert the electrode or wire into the welding machine, following the manufacturer’s instructions.

Finally, double-check all the connections and ensure that the welding machine is functioning properly before proceeding to the next step.

faqs for How To Weld Metal Beads:

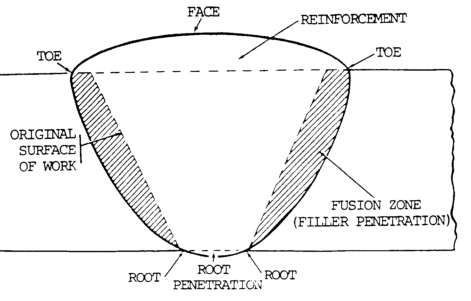

Welding metal beads is a fundamental process in metal fabrication and repair. The purpose of welding metal beads is to join two or more metal pieces together, creating a strong and durable bond. This technique is commonly used in industries such as construction, automotive, and manufacturing. By welding metal beads, you can create structures, repair damaged parts, or add reinforcements to existing metal components.

It is important to note that the quality of the weld is crucial for ensuring the integrity and strength of the joint. Properly executed welds can provide a permanent and reliable connection between metal pieces, making them essential in various applications.

To weld metal beads, you will need several pieces of equipment. The basic equipment includes a welding machine, welding electrodes or filler wire, welding helmet, welding gloves, and protective clothing such as a welding jacket and apron.

It is essential to use the appropriate type of welding machine and electrodes or filler wire for the specific metal you are working with. Different metals require different welding processes and consumables. Therefore, it is crucial to select the right equipment and materials for your welding project to ensure a successful and strong weld.

Welding metal beads involves working with high temperatures, sparks, and potentially toxic fumes. Therefore, it is essential to take proper safety precautions to protect yourself and those around you. Here are some safety measures to consider:

1. Wear appropriate personal protective equipment (PPE) such as a welding helmet, gloves, and protective clothing to shield yourself from heat, sparks, and UV radiation.

2. Ensure proper ventilation in your workspace to prevent the accumulation of harmful fumes and gases. If working indoors, use exhaust fans or open doors and windows to allow fresh air circulation.

3. Keep a fire extinguisher nearby and know how to use it in case of any fire hazards.

4. Inspect your equipment regularly and ensure it is in good working condition to avoid any malfunctions or accidents.

There are several welding techniques commonly used for welding metal beads. The choice of technique depends on the type of metal, joint configuration, and desired weld characteristics. Here are some common welding techniques:

1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a versatile and widely used welding process. It involves using a consumable electrode coated in flux to create the arc and deposit metal into the joint.

2. Gas Metal Arc Welding (GMAW): This process, also known as MIG welding, uses a continuous wire electrode and a shielding gas to protect the weld from atmospheric contamination.

3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular electrode filled with flux to shield the weld. It is commonly used for outdoor applications or in windy conditions.

4. Tungsten Inert Gas Welding (TIG): TIG welding uses a non-consumable tungsten electrode to create the arc and a separate filler wire to add metal to the joint. It produces high-quality welds and is commonly used for thin materials or critical applications.

Welding metal beads can present various challenges that may affect the quality and strength of the weld. Here are some common challenges that welders often face:

1. Welding distortion: Heat generated during welding can cause metal to expand and contract, resulting in distortion or warping. Proper techniques such as preheating, controlling heat input, and using fixtures or clamps can help minimize distortion.

2. Weld porosity: Porosity refers to the presence of small gas pockets within the weld, which can weaken the joint. It can be caused by factors like moisture, improper shielding gas, or contaminants on the metal surfaces. Ensuring proper cleanliness and using appropriate shielding gas can help prevent porosity.

3. Lack of fusion or incomplete penetration: Inadequate fusion or penetration can occur when the welding heat is insufficient or the welding speed is too fast. This can result in weak or incomplete welds. Adjusting the welding parameters and maintaining proper technique can help achieve full fusion and penetration.

4. Cracking: Cracks can occur in the weld or adjacent base metal due to factors such as improper cooling, high stresses, or metallurgical issues. Proper joint preparation, controlling heat input, and using appropriate filler materials can help minimize the risk of cracking.

Source: weldguru.com

conclusion:

learning how to weld metal beads is a valuable skill that can open up a world of opportunities for individuals in various industries. Whether you are a hobbyist looking to create intricate metalwork or a professional seeking to enhance your skill set, mastering the art of welding metal beads can be a game-changer. By following the steps and techniques outlined in this guide, you can confidently embark on your welding journey and create strong, durable, and visually appealing metal bead welds.

Remember, practice makes perfect. As with any skill, becoming proficient in welding metal beads requires dedication, patience, and continuous learning. Don’t be discouraged if your first attempts are less than perfect – it’s all part of the learning process. With time and experience, you will develop a keen eye for detail, a steady hand, and the ability to create flawless metal bead welds. So, grab your welding gear, ignite your passion for craftsmanship, and let your creativity flow as you embark on this exciting journey into the world of welding metal beads.