welding vs soldering vs brazing- which one is for you?

Today we discuss welding vs soldering vs brazing. In the world of metalworking, there are a lot of different ways to join two pieces together. One way is welding, Another common method is soldering. Brazing is also an option for joining metal parts together. A lot of people don’t know the differences between welding, soldering, and brazing. The process of welding, soldering, and brazing are all methods for joining metal parts together. The difference between the three processes is in how they join metal parts. Here we know the details.

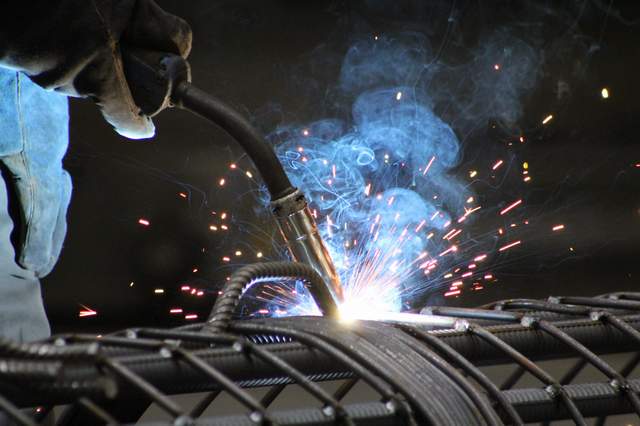

What is welding :

Welding is a method of joining materials such as metals, plastics, and other materials by causing fusion. Welding uses heat and pressure to create a molecular bond between two pieces. The welding process uses heat to melt the components at high temperatures and then fuses them together with pressure or electricity. this is also known as ‘flame cutting’.

The usage of welding: Welding has been around for centuries and was originally used to build ships, but today it’s being used to construct much more than that.it has evolved into an important part of society with its usage ranging from construction, automotive work, and even home improvement projects.

What is soldering :

The word solder comes from an Old English word meaning “to flow together” or “make liquid.”Soldering is a process used to join two metal parts together by melting a filler metal and then applying it. The filler metal melts at a lower temperature than the base metals being joined so that they flow together and cool into an amalgamated mass. It is not as strong as welding but is also less expensive, so it’s often used for joining copper pipes or aluminum wiring.

The usage of soldering: Soldering can be done with a variety of metals, including copper, steel, silver, and gold. It was originally used as an ancient form of joining iron-based materials such as bronze or brass. Today it’s most commonly used in soldered joints for plumbing pipes and electrical wiring connections. In electronics, soldering can be used to attach wires to circuit boards or components such as resistors or capacitors. Soldering irons are available in different wattages.

What is brazing :

The word brazing comes from a French term meaning “to burn” (Brule). Brazing is a metal joining process that uses heat to join two pieces of similar or dissimilar metals. The filler material can be an alloy or pure elemental metal depending on the application and process used. Brazing differs from welding in that it does not involve melting the base materials, but rather heating them beyond their melting point. This process can also be done without preheating, known as cold pressure brazing.

The usage of brazing: Brazing has been around since before 1900 BC and was used to join copper tubing for plumbing applications in Ancient Egypt! Brazing is an economical and efficient joining method that can be used in many different industries. Today brazed joints are commonly found in many industries including aerospace, medical, oil & gas, nuclear power generation, and more! A few examples include jet engines, water-cooled radiators, or even joining parts of watch movements such as wheels.

Tips on how to solder and braze well:

- Use the right tools.

- Practice on scrap material before you try it on your project.

- Keep a wet sponge nearby to cool metal quickly.

- Try different techniques until you find one that works for you or use what is best suited for the type of job at hand.

- always wear gloves and goggles when working with hot metal, have fire extinguisher handy, and do not work in an area where there are any flammable materials nearby.

- Let the brazing material cool before moving it or touching it with bare hands.

Welding vs soldering vs brazing – which one should I choose:

- Brazing is similar to soldering, but it uses an alloy that melts at lower temperatures than those required for soldering.

- For example, if you need a mechanical joint where strength matters more than appearance, welding would be your best option.

- If you want something that looks nice as well as performs well mechanically, brazing or soldering would be better options.

- Soldering is a good choice for joining metals that are not to be subjected to much stress or vibration.

- Brazing can be used to join metals that have been heated and then cooled, as the heat from the brazing process will make it possible for them to bond together.

- Welding is a very versatile technique that can be used on materials of different thicknesses and shapes. Welded joints are stronger than both solder and braze joints

- All three techniques offer their own benefits – welding is more expensive but offers better long-term performance, while soldering saves on costs but has lower strength than both welding and brazing.

- one of the differences between welding, soldering, and brazing is that welding requires higher temperatures than either soldering or brazing.

- When choosing between these three techniques, consider what type of material you’re working with and how often it will need repairs before making your decision.

- The most important thing when deciding which technique you should use is knowing what you want your finished product to look like.

- Welders use arc welding techniques for steel workpieces while gas-shielded flux-cored wire processes are used for aluminum alloys.

faqs for welding vs soldering vs brazing

The reason is that welding allows you to use metal alloy types with better strength characteristics than might be found in a brazing or solder joint.

everything else is dependent on what type of material it actually is. With aluminum, for example, you can join pieces together by welding them since it doesn’t melt at the same temperature as steel does. Brazing also looks different from soldering and will typically use an acid flux to clean off any oxide that forms during prolonged storage or usage.

Welding is done in industrial environments where heat and material specifications are not an issue. Welding can be dangerous without a skilled welder to do it correctly. Soldering is usually used when a fluid metal of a very high melting point needs to be joined to a less difficult-to-hold molten metal at a lower melting point. brazing involves flux cleaning and generally more moving parts from start to end.

Final words:

Choosing the right welding process for your project will depend on many factors. The type of material, shape, and size are just a few variables that can impact which welding technique is best for you. If you’re not sure what to do next, contact us! Our team has more than two decades of experience in all types of metalwork projects.