How To Weld In Tight Spaces

Today we discuss How To Weld In Tight Spaces. When it comes to welding in tight spots, it’s all about technique and preparation. First and foremost, you need to ensure you have the right safety gear on hand. Safety goggles, gloves, and protective clothing are essential to protect yourself from sparks and heat. Once you’re geared up, you can focus on positioning yourself and your equipment to maximize your workspace.

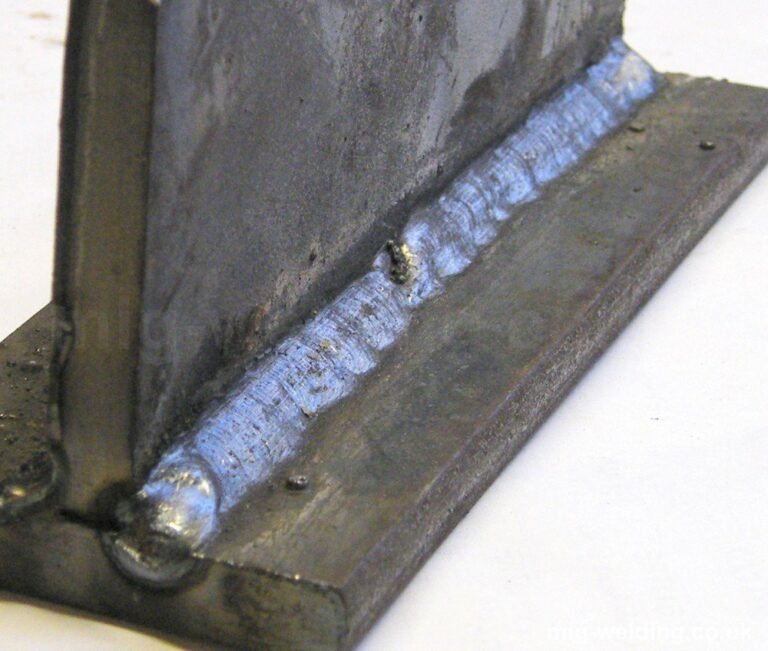

One helpful technique for welding in tight spaces is called “tacking.” This involves making small welds, or tack welds, to hold the pieces in place before doing the final weld. Tack welding allows you to adjust the joint or move around more easily if needed. By breaking the job down into smaller steps, you can work more efficiently and achieve better results. So, let’s get ready and master the art of welding in tight spaces!

Features:

- Prepare your workspace by clearing any obstructions.

- Put on protective gear, including gloves, goggles, and a welding helmet.

- Position your welding machine in a safe and accessible location.

- Use smaller welding tools, such as a TIG welder or a welding clamp, for better maneuverability.

- Take your time and focus on precision to ensure a strong and accurate weld.

How To Weld In Tight Spaces:

1. Assessing the Workspace: Proper Planning for Successful Welding

Before you start welding in a tight space, it’s crucial to assess the workspace thoroughly. Take the time to visualize the process and consider factors such as access points, clearance, safety hazards, and the need for additional support. This planning phase will save you time and frustration down the line.

Create a checklist of equipment, materials, and tools needed for the task. In the limited space, having everything within reach is vital. Make sure you have enough clearance to maneuver and that you’re aware of any potential obstacles that could impede your work. It’s also essential to address any safety concerns and take appropriate precautions, such as wearing protective gear and ensuring proper ventilation.

Consider utilizing mock-ups or test welds in a more accessible area to ensure you have the right technique and settings before working in a confined space. This practice will give you the confidence to tackle the job smoothly and minimize the risk of errors or rework.

2. Choosing the Right Welding Process and Electrode: Matching the Method to the Space

Different welding processes offer varying advantages when working in tight spaces. Take into account factors such as the type and thickness of the material, required penetration, and the available power source. For instance, Tungsten Inert Gas (TIG) welding is often preferred for its precision, while Shielded Metal Arc Welding (SMAW) can be advantageous in situations with limited visibility.

Equally important is selecting the electrode or filler metal that best suits the project at hand. Consider the material’s compatibility, weld positions, and space limitations. Be mindful of the electrode diameter, as smaller diameters are often more suitable for tight spaces due to increased maneuverability.

Experimenting with different welding processes, electrodes, and filler metals in advance can help you determine the best combination for the specific requirements of the confined workspace. Practice on scrap material or conduct tests to evaluate the weld quality, strength, and appearance.

3. Navigating Limited Visibility: Illumination Techniques and Aids

Working in tight spaces often means dealing with poor visibility. Proper illumination is essential to ensure accurate weld placement and monitoring. Use a combination of directed lighting and task lighting to brighten the workspace. Position light sources strategically to minimize shadows and provide a clear view of the welding area.

Consider using specialized welding helmets or masks with built-in lighting systems. These innovative tools provide focused illumination, enabling you to see your work more clearly in confined spaces. Additionally, be sure to protect your eyes by using a helmet with appropriate shade selection for the welding process being used.

If the confined space doesn’t allow for adequate lighting solutions, consider incorporating additional aids such as mirrors, telescopic tools, or video cameras. These tools can provide enhanced visibility and allow you to monitor the welding process without straining to physically see the work.

4. Adapting Techniques and Body Positioning for Limited Space

In tight spaces, your body positioning is crucial for maneuverability and stability. Optimize your posture and technique by ensuring a secure footing and a balanced stance. Use your available space efficiently, making small, controlled movements to navigate around obstacles and achieve the desired weld joint positions.

Consider using ergonomic aids such as adjustable arm positioners or magnetic support devices. These tools can provide additional stability and precision when working in constrained positions. Experiment with different positions and utilize supports whenever possible to reduce physical strain and improve welding accuracy.

Furthermore, consider the use of joint preparation techniques that enable welding from a single side whenever feasible. This minimizes the need for complex maneuvering and reduces the risk of errors or inconsistencies. Similarly, employ techniques like tack welding or skip welding to secure the joints temporarily before final welding, allowing for improved maneuverability and access.

5. Practice, Patience, and Persistence: Developing Mastery in Tight Spaces

Welding in tight spaces requires practice, patience, and a willingness to adapt. It is important to develop a steady hand, spatial awareness, and the ability to troubleshoot in real-time. Start with smaller projects and gradually challenge yourself with more complex tasks as you gain confidence and experience.

Seek opportunities to learn from experienced welders who have mastered the art of welding in tight spaces. Their insights and advice can provide invaluable guidance for overcoming challenges and honing your skills. Online forums, trade-specific communities, or local welding clubs are great places to connect with such individuals.

Remember that the journey towards mastering tight space welding can be demanding but immensely rewarding. Embrace each project as an opportunity for growth and improvement. Through consistent practice, patience, and persistence, you will develop the expertise to tackle any welding job, regardless of the confined workspace.

Conclusion

Mastering the art of welding in tight spaces opens up a world of possibilities for welders. By understanding the challenges, utilizing the right techniques and equipment, and continuously improving your skills, you can confidently tackle welding projects in even the most cramped and challenging environments. With practice, patience, and persistence, you will become a skilled welder capable of producing high-quality welds regardless of the constraints. Remember to plan meticulously, adapt to the circumstances, and enjoy the journey of exploring your welding prowess in the world of tight spaces.

Key Takeaways: How To Weld In Tight Spaces

- Plan your workspace by clearing any obstacles and ensuring proper ventilation.

- Use a smaller welding machine or a specialized welding torch for better maneuverability.

- Master the technique of tack welding to secure your components before completing the final welds.

- Employ the right welding position, such as the push or drag technique, to reach tight corners.

- Choose the appropriate welding electrode or wire to ensure proper penetration and control.

faqs for How To Weld In Tight Spaces:

When welding in tight spaces, it’s important to find a comfortable position that allows you to maneuver easily. One technique is to use a stool or chair with a swivel seat, which enables you to rotate your body without straining.

Another option is to use a welding positioner, which is a tool that holds your workpiece at the desired angle so you can weld more comfortably. Experiment with different positions and tools to find what works best for you, ensuring that you maintain a stable and comfortable posture throughout the welding process.

Working in tight spaces can present some hazards, so it’s crucial to take safety precautions. Make sure the area is well-ventilated to prevent the accumulation of harmful fumes. Wear appropriate protective gear such as a welding helmet, gloves, and flame-resistant clothing to shield yourself from sparks and heat.

Before starting, clear the area of any flammable materials or debris that could be ignited during the welding process. If possible, use welding curtains or screens to isolate the workspace and protect nearby objects from potential damage. Finally, never forget to conduct a thorough inspection of your welding equipment to ensure it is in good working condition before starting any welding job.

Yes, there are specialized welding techniques that can be used in tight spaces. One method is called “back welding,” which involves welding from the opposite side of the joint. This allows you to access tight spaces without compromising the quality of the weld.

Another technique is “tack welding,” where you create small tack welds to temporarily hold the workpieces together before the final welding. Tack welding allows you to assemble complex structures in tight spaces more easily.

When working in tight spaces, a compact and portable welding machine is ideal. Look for a machine that is lightweight and has a small footprint, as this will make it easier to maneuver and position in tight areas. Inverter welders are a popular choice for welding in tight spaces due to their compact size and versatility.

Consider machines that offer advanced features like adjustable arc force, which can enhance your control and adaptability in confined workspaces.

Ensuring the quality of the weld in tight spaces requires careful attention to detail. First, make sure you have good visibility of the joint by using proper lighting or additional tools such as flashlights or work lights. This will help you detect any potential defects or imperfections during the welding process.

Next, take your time and focus on maintaining a steady hand to achieve precise control over the torch or electrode. Be aware of the surroundings and make sure there is enough space to work without accidentally damaging the weld or the surrounding materials. Finally, perform regular inspections to check for any signs of cracks, porosity, or other defects that may compromise the integrity of the weld.

HOW TO GET YOUR WELDS INTO TIGHT GAPS/ ROLL CAGE WELDING

Summary:

Welding in tight spaces can be challenging, but with the right techniques, it can be done successfully. Remember to prioritize safety by wearing protective gear and ensuring proper ventilation. Plan ahead and prepare your workspace by clearing clutter and protecting nearby objects. Choose the right welding method and equipment for the specific task at hand. Practice patience and precision while working in tight spaces, as it requires careful control and attention to detail.